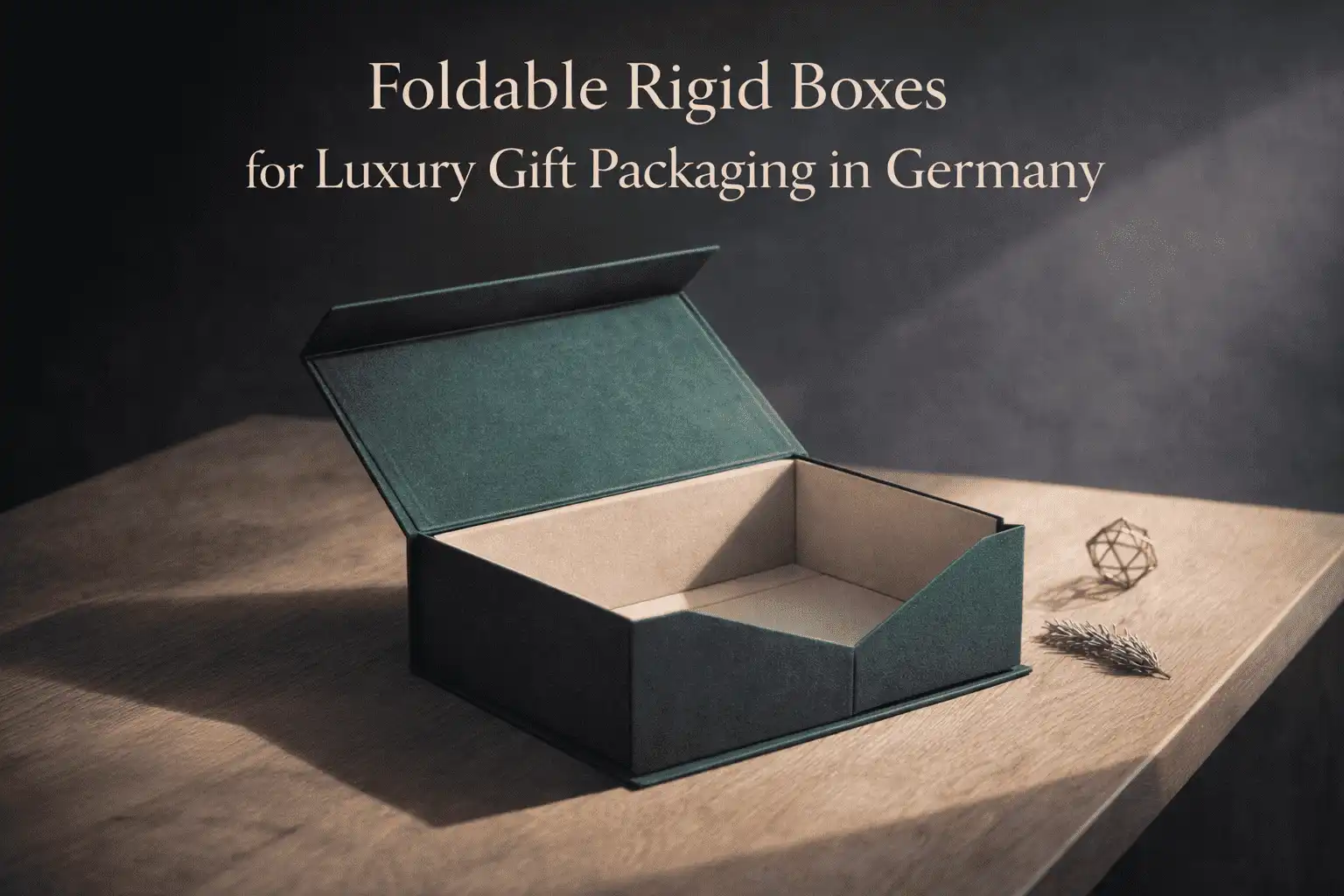

Foldable Rigid Boxes for Luxury Gift Packaging in Germany

Imagine investing thousands of euros in premium products, only to watch profit margins evaporate due to excessive shipping costs and warehouse storage fees. This is the daily reality for luxury brands across Germany seeking sophisticated packaging that doesn't compromise their bottom line. The foldable rigid box emerges as the transformative solution, combining the structural integrity and premium aesthetics of traditional rigid packaging with space-saving innovation that reduces logistics expenses by over 60%. For German luxury brands in cosmetics, electronics, and gourmet food sectors, this packaging technology represents not just a cost-reduction strategy but a competitive advantage in an increasingly demanding marketplace where both sustainability and presentation excellence are non-negotiable.

Why German Luxury Brands Are Transitioning to Foldable Rigid Box Solutions?

The German luxury goods market operates within unique constraints that make conventional rigid packaging increasingly problematic. Traditional non-collapsible gift boxes occupy enormous warehouse space, forcing brands to maintain costly storage facilities while limiting inventory flexibility. When shipping from manufacturing centers in Asia to distribution points across Germany, these bulky packages fill container space inefficiently, multiplying freight costs unnecessarily. The foldable rigid box addresses these pain points through ingenious engineering that allows boxes to ship and store flat, then assemble quickly at point-of-use. This design innovation delivers the same premium unboxing experience customers expect from luxury brands while slashing supply chain expenses that directly impact profitability. German brands partnering with experienced manufacturers can now access foldable rigid box designs in three distinct size categories—Large configurations for products measuring 100-150mm in height, Medium variants accommodating 50-100mm items, and Tiny formats perfect for jewelry and small cosmetics ranging 20-50mm. Each size category utilizes proprietary structural engineering protected by manufacturing patents, ensuring consistent performance and assembly reliability across production runs.

The Engineering Advantage Behind Collapsible Rigid Construction

The technical sophistication separating premium foldable rigid box designs from standard collapsible packaging lies in material selection and structural precision engineering. High-quality implementations utilize grey chipboard or duplex chipboard as the rigid foundation, providing the necessary structural integrity to support luxury products while maintaining collapsibility. These chipboards undergo compression manufacturing processes that create multi-ply construction with exceptional resistance to bending and deformation, crucial for protecting valuable contents during transit and shelf display. The exterior surfaces receive lamination with premium paperboard materials—typically SBS C1S or SBS C2S grades manufactured from virgin bleached wood pulp that delivers the bright white appearance and smooth printing surface luxury brands require. This dual-layer construction strategy combines the cost-efficiency and recyclability of chipboard cores with the visual sophistication of coated printing surfaces, creating foldable rigid box packaging that commands attention on retail shelves while meeting sustainability expectations. The manufacturing process incorporates precision die-cutting and creasing operations that establish exact fold lines, enabling boxes to collapse completely flat for shipping yet spring into rigid form during simple assembly procedures requiring no adhesives or complex instructions.

Material Options That Define Luxury Presentation Standards

Premium foldable rigid box production offers diverse material specifications tailored to specific brand positioning and product requirements. For ultra-premium applications where visual impact justifies higher material costs, SBS C2S paperboard delivers exceptional performance with coating on both sides, ensuring brilliant color reproduction and fine detail resolution on all visible surfaces. This material choice proves particularly valuable for luxury cosmetics packaging and high-end electronics where interior box surfaces receive printing as part of the unboxing ritual, creating memorable brand experiences that justify premium pricing. Brands seeking balance between cost-efficiency and premium appearance frequently specify SBS C1S configurations, featuring one coated side for exterior printing excellence while the uncoated reverse provides superior adhesion for lamination to rigid substrates. For brands emphasizing sustainability credentials alongside luxury positioning, CCNB paperboard manufactured from recycled fibers offers environmental benefits with acceptable print quality for many applications, particularly when combined with specialty finishing techniques that elevate perceived value. The selection between these materials depends on brand strategy, target market positioning, and specific product protection requirements, with experienced packaging engineers providing guidance on optimal specifications during the consultation phase. Beyond base materials, luxury foldable rigid box designs incorporate specialty papers including metallic finishes that deliver mirror-like sheens in gold, silver, copper or custom color formulations, instantly elevating packaging sophistication and shelf presence at retail environments.

Advanced Finishing Techniques for Distinctive Brand Identity

The surface of a foldable rigid box serves as a critical brand communication canvas where luxury manufacturers differentiate themselves from competitors through sophisticated finishing applications. Hot foil stamping represents one of the most effective techniques for creating premium visual impact, transferring metallic or pigmented foil onto specific design areas using precision heat and pressure application. This process delivers brilliant metallic sheens impossible to achieve through conventional printing, making logos, brand names, and decorative elements literally shine with gold, silver, rose gold, or holographic effects that catch light and consumer attention simultaneously. German luxury brands particularly appreciate the anti-counterfeiting benefits of holographic foil stamping, where laser-etched microscopic patterns create angle-shifting color effects and subtle textures that prove extremely difficult for counterfeiters to replicate accurately. For brands seeking tactile differentiation, embossing and debossing techniques press paper between precision-matched male and female dies, creating raised or recessed three-dimensional relief patterns that invite touch and communicate quality through haptic feedback. These dimensional effects work synergistically with visual treatments—imagine debossed brand lettering filled with metallic foil, or embossed patterns highlighted with spot UV coating that creates brilliant gloss contrast against matte surroundings. The combination possibilities are virtually limitless, enabling packaging designers to craft distinctive sensory signatures that reinforce brand identity across every customer touchpoint.

UV Coating Applications That Enhance Visual Drama

Spot UV coating technology offers luxury brands exceptional creative flexibility for foldable rigid box decoration, allowing designers to apply high-gloss varnish to specific design elements while leaving surrounding areas in contrasting matte finish. The process involves spreading liquid UV-curable varnish onto selected areas through screen printing methods, then instantly curing the coating under ultraviolet light to create hard, brilliant surfaces with exceptional clarity and depth. This selective application creates dramatic visual and tactile contrast—picture a matte black foldable rigid box surface where only the brand logo appears in mirror-bright spot UV, or product photography printed in standard inks with spot UV highlights that make water droplets or jewelry facets appear almost three-dimensional. Beyond pure aesthetics, UV coatings provide practical protection benefits, creating scratch-resistant and moisture-resistant barriers that maintain packaging appearance throughout distribution, retail display, and customer handling. For foldable rigid box applications, UV coatings prove particularly valuable because they add minimal thickness and weight, preserving the collapsibility that makes this packaging format economically advantageous. Brands can specify overall UV coating for complete surface protection with uniform gloss, or combine spot UV with embossing techniques in what specialists call "combination finishing"—first applying spot UV coating, then embossing the same areas to create elements that are simultaneously shiny and raised, delivering maximum visual impact and tactile interest that communicates luxury without requiring expensive materials throughout the entire package structure.

Cost Optimization Strategies for German Market Distribution

The financial advantages driving foldable rigid box adoption across German luxury sectors extend well beyond simple material costs, encompassing entire supply chain transformation. When manufacturers ship traditional rigid gift boxes from production facilities to German distribution centers, each container holds perhaps 3,000-5,000 assembled boxes depending on dimensions, with most container volume occupied by empty air space inside the rigid structures. Those same box designs in collapsible format can ship 10,000-15,000 units per container, more than tripling container utilization efficiency and proportionally reducing per-unit freight expenses. This shipping optimization becomes particularly significant for German importers managing transcontinental logistics from Asian manufacturing centers, where container costs, customs duties calculated on shipment volume, and handling fees all decrease dramatically with higher-density shipments. The mathematics prove compelling—a foldable rigid box design delivering 60% shipping cost reduction compared to traditional rigid boxes, and 20-30% savings versus standard collapsible alternatives, directly improves product margins by several percentage points in highly competitive luxury markets where pricing pressure remains constant. Beyond initial logistics, warehouse storage efficiency improvements generate ongoing cost benefits, as collapsed boxes occupy minimal floor space in distribution centers, reducing facility size requirements and associated rent, climate control, and handling expenses. Brands maintaining inventory for seasonal peaks or promotional campaigns find they can stock significantly larger volumes without expanding warehouse capacity, improving responsiveness to market demand while controlling fixed costs.

Production Efficiency Through Automated Manufacturing Systems

Modern foldable rigid box production incorporates advanced automation technologies that simultaneously improve quality consistency and reduce manufacturing timelines compared to handcrafted rigid box assembly. Automated visual positioning systems utilize high-resolution cameras and computer vision algorithms to precisely align printed sheets during die-cutting, gluing, and assembly operations, ensuring that every box meets exact dimensional tolerances and visual registration standards. This technological approach proves particularly valuable for luxury applications where even millimeter-level misalignments or visible glue marks would compromise perceived quality and damage brand reputation. The production workflow begins with offset, digital, or flexographic printing that transfers designs onto selected paperboard materials with vibrant color reproduction and fine detail resolution suitable for complex graphics, photographic imagery, and small typography. Following printing, surface finishing operations apply coatings, varnishes, foil stamping, embossing, or other specialty treatments according to approved specifications. The lamination or mounting phase bonds printed sheets to rigid chipboard substrates, creating the structural foundation that gives foldable rigid boxes their characteristic strength and premium feel. Precision die-cutting equipment uses custom-manufactured metal dies to cut exact shapes, create windows or viewing panels, and establish crease lines that enable proper folding action. Finally, gluing and assembly operations fold and bond die-cut pieces into finished boxes using specialized adhesives formulated for strength, clean application, and rapid curing. Throughout this process, quality control systems monitor critical parameters, rejecting any units failing to meet established standards before packing and shipping operations dispatch completed products to client distribution networks.

Environmental Sustainability Credentials Meeting German Standards

German consumers and regulatory frameworks increasingly demand that luxury packaging demonstrate genuine environmental responsibility alongside aesthetic excellence. The foldable rigid box format inherently addresses multiple sustainability concerns through design efficiency and material selection strategies. The dramatic reduction in shipping volume translates directly to reduced fuel consumption and carbon emissions across international logistics networks—when three times as many boxes fit in each container, transportation-related environmental impact decreases proportionally. This logistics efficiency matters enormously for German brands committed to science-based carbon reduction targets and transparent sustainability reporting. Material composition further enhances environmental credentials when manufacturers specify recycled-content chipboards for rigid structural components, FSC-certified paperboards for printing surfaces, and water-based adhesives throughout assembly processes. Grey chipboard and duplex chipboard cores manufactured primarily from post-consumer waste paper support circular economy principles while delivering necessary structural performance, and both materials remain fully recyclable at end-of-life through standard paper recycling streams accessible throughout Germany. Leading manufacturers maintain certifications including ISO14001 Environmental Management Systems that establish formal protocols for minimizing waste generation, controlling emissions, managing hazardous materials, and continuously improving environmental performance across operations. For German luxury brands seeking to validate sustainability claims, partnership with certified manufacturers provides documentary evidence supporting marketing communications and corporate responsibility reporting. The combination of reduced transportation impact, recycled material content, recyclability, and certified environmental management systems creates comprehensive sustainability stories that resonate with environmentally-conscious German consumers willing to pay premium prices for brands demonstrating authentic commitment to environmental stewardship.

Quality Certifications Ensuring Consistent Excellence

Beyond environmental credentials, comprehensive quality management certifications provide German luxury brands with confidence in manufacturing consistency and product safety. ISO9001 Quality Management System certification establishes formal processes governing every aspect of production, from incoming material inspection through final product testing and customer feedback integration. These standardized protocols ensure that foldable rigid boxes manufactured today deliver identical performance and appearance to those produced six months ago or six months in the future, critical for brands maintaining consistent market presence across extended product lifecycles. For luxury goods requiring direct food contact or pharmaceutical applications, additional certifications verify that materials and manufacturing processes meet stringent safety standards prohibiting migration of harmful substances into packaged products. SMETA social compliance auditing demonstrates commitment to ethical labor practices, workplace safety, and fair employment standards throughout manufacturing operations, increasingly important for German brands facing stakeholder scrutiny regarding supply chain responsibility. G7 Color Management certification guarantees precise color reproduction across different printing technologies and production runs, essential for luxury brands where color accuracy directly impacts brand recognition and perceived quality. Companies serving premium clients often maintain specialized certifications including Disney approval for character licensing applications, demonstrating capability to meet exceptionally rigorous quality and social responsibility standards demanded by global intellectual property holders. This certification portfolio reduces risk for German luxury brands by providing third-party validation of manufacturing competence, quality systems, and ethical operations, facilitating confident partnerships that support long-term business relationships.

Conclusion

Foldable rigid box technology revolutionizes luxury packaging economics without compromising the premium presentation German brands require, delivering 60% shipping cost reductions alongside sophisticated finishing capabilities including foil stamping, embossing, and spot UV treatments that create distinctive brand experiences.

Cooperate with GUANGZHOU FETCHING COLOR PRINTING & PACKAGING LTD.

As a leading China foldable rigid box manufacturer with over 25 years of experience since 1999, Guangzhou Fetching Color Printing & Packaging Ltd. operates a 30,000㎡ facility housing advanced equipment including KBA106 UV printing machines and Heidelberg XL162-6L presses serving 1,000+ loyal customers across food, cosmetics, electronics, and personal care industries. Our China foldable rigid box factory maintains ISO9001, ISO14001, FSC, SMETA, G7, and Disney certifications while our team of 10+ senior packaging engineers develops innovative structures protected by proprietary patents. We offer High Quality foldable rigid box solutions with competitive foldable rigid box price structures and flexible foldable rigid box wholesale programs. As your trusted China foldable rigid box supplier, we provide foldable rigid box for sale in Large, Medium, and Tiny sizes with complete customization capabilities. Contact public@fetchingprinting.com today to discuss your luxury packaging requirements and discover how our expertise transforms your brand presentation while optimizing supply chain costs.

References

1. "Sustainable Packaging in the European Luxury Goods Sector: Consumer Perceptions and Material Innovations" - Schmidt, H., Weber, K., and Müller, T. (2024). Journal of Packaging Technology and Research.

2. "Collapsible Rigid Box Engineering: Structural Design Principles for Premium Gift Packaging" - Anderson, R. and Chen, L. (2023). International Packaging Design Quarterly.

3. "Supply Chain Optimization Through Advanced Packaging Formats: Case Studies from German Consumer Goods" - Becker, M. and Hoffmann, S. (2024). European Logistics Management Review.

4. "Environmental Impact Assessment of Packaging Materials in Luxury Product Distribution" - Thompson, J., Wagner, A., and Fischer, P. (2023). Sustainability in Packaging Systems.

5. "Surface Finishing Technologies for High-End Paperboard Packaging: Technical Applications and Market Trends" - Williams, D. and Zhou, Y. (2024). Printing and Coating Technology International.

Based on your location and order quantity, you will have the opportunity to receive a limited time free shipping promotion!

Corporate Purpose