When ordering collapsible rigid boxes from suppliers, you should check their structural integrity, material quality, customization capabilities, production certifications, and cost-effectiveness. A collapsible rigid box offers space-saving storage while maintaining premium presentation quality, making careful supplier evaluation crucial for successful procurement. Verifying these elements ensures your packaging meets both functional requirements and brand standards while optimizing logistics costs.

Understanding Collapsible Rigid Boxes: What You Need to Know Before Ordering

Collapsible rigid boxes represent an innovative packaging solution that bridges the gap between traditional rigid boxes and space-efficient storage needs. These boxes combine the structural strength of conventional rigid packaging with the convenience of fold-flat storage, making them particularly valuable for luxury and bulk packaging applications.

-

What Is a Collapsible Rigid Box?

A collapsible rigid box features a unique design that allows it to flatten for storage and shipping while maintaining the premium appearance and structural integrity of traditional rigid packaging when assembled. Unlike standard folding cartons, these boxes use reinforced materials and specialized construction techniques to ensure durability and visual appeal. The fundamental difference between collapsible rigid boxes and other packaging options lies in their construction methodology. While folding cartons rely on simple score lines and basic folds, collapsible rigid packaging incorporates sophisticated engineering to maintain box integrity through multiple assembly and disassembly cycles. This makes them superior to standard options for high-end product presentation.

-

Benefits and Applications of Collapsible Rigid Boxes

The logistics advantages of collapsible rigid packaging are substantial and measurable. These boxes can reduce shipping and storage costs by more than 60% compared to traditional rigid gift boxes, while offering 20%-30% cost savings over standard collapsible alternatives. This efficiency stems from their ability to ship flat and assemble on-demand. Applications span multiple industries, from luxury cosmetics and electronics to high-end retail merchandise. The premium presentation quality makes them ideal for magnetic gift boxes, while their space-saving characteristics benefit bulk packaging operations. Companies using these solutions report improved warehouse efficiency and reduced transportation expenses.

-

Key Design and Material Considerations

Material selection significantly impacts both performance and cost. Premium substrates like SBS C1S offer exceptional printability with bright white appearance and excellent structural integrity, making them perfect for luxury applications. SBS C2S provides dual-side coating for sophisticated interior and exterior designs, while CCNB offers cost-effective solutions with good print quality for budget-conscious projects. Design elements affecting functionality include reinforcement placement, fold mechanisms, and assembly methods. The most advanced solutions incorporate proprietary structures with patent protection, ensuring consistent performance and competitive advantages for procurement managers seeking reliable packaging solutions.

Critical Criteria to Evaluate Collapsible Rigid Box Suppliers

Supplier evaluation extends far beyond price comparisons, encompassing reputation assessment, certification verification, and manufacturing capability analysis. Comprehensive evaluation protects against quality inconsistencies and delivery disruptions that can impact your supply chain.

-

Supplier Reputation and Certifications

Verified certifications serve as quality benchmarks that indicate supplier compliance with international standards. Essential certifications include ISO14001-2015 Environmental Management System, ISO9001-2015 Quality Management System, FSC certification for sustainable materials, and industry-specific approvals like Disney certification for entertainment products. Client testimonials and case studies provide valuable insights into real-world performance and customer satisfaction levels. Suppliers with extensive experience, such as those operating since 1999 with over 300 employees and serving more than 1,000 loyal customers, demonstrate proven track records in delivering consistent quality and service reliability.

-

Quality Control and Manufacturing Capabilities

Advanced manufacturing capabilities directly correlate with product quality and delivery reliability. Leading suppliers utilize state-of-the-art equipment including KBA106-(9+1) UV printing machines, Heidelberg XL162-6L printing systems, and automated visual positioning production lines that ensure short production times and stable quality outcomes. Scalability becomes crucial when evaluating suppliers for long-term partnerships. Facilities spanning 35,000 square meters with comprehensive R&D departments staffed by experienced packaging engineers can accommodate growing demand while maintaining quality standards. Production capacity and technological sophistication determine whether suppliers can handle volume fluctuations effectively.

-

Customization Options and Technical Support

Customization capabilities encompass structural modifications, surface treatments, and branding integration. Advanced suppliers offer multiple size options with proprietary structures, such as Large (100-150mm height), Medium (50-100mm height), and Tiny (20-50mm height) configurations, each designed for specific magnetic gift box applications. Surface enhancement options include hot foil stamping, UV coating, embossing, and frosted touch finishes that elevate packaging visual impact. Technical support during design and prototyping phases ensures optimal results and reduces development timelines, making supplier collaboration essential for complex projects.

-

Eco-Friendly Practices and Sustainability Commitment

Environmental responsibility increasingly influences procurement decisions, making supplier sustainability practices crucial evaluation criteria. Suppliers offering recyclable materials, biodegradable substrates, and FSC-certified options align with corporate environmental goals while meeting consumer expectations for responsible packaging. Comprehensive environmental management systems, evidenced by ISO14001 certification, demonstrate genuine commitment to sustainable operations. These practices extend beyond material selection to encompass manufacturing processes, waste reduction, and energy efficiency initiatives that support long-term environmental goals.

Comparing Collapsible Rigid Boxes: Making the Right Procurement Decision

Procurement managers must evaluate multiple factors when comparing packaging options, balancing functionality, cost-effectiveness, and brand presentation requirements. Understanding these trade-offs enables strategic decisions that optimize both operational efficiency and customer satisfaction.

-

Collapsible Rigid Box vs Regular Rigid Box – Pros and Cons

Regular rigid boxes excel in immediate usability and maximum structural integrity but suffer from significant storage and shipping inefficiencies. They occupy full volume regardless of use status, creating substantial logistics costs and warehouse space requirements. However, they offer superior protection for fragile items and maintain consistent premium presentation. Collapsible alternatives provide dramatic space savings and logistics cost reductions while maintaining adequate protection for most applications. The trade-off involves slightly more complex assembly processes and potential limitations for extremely heavy or fragile products. The 60% shipping cost reduction often justifies these minor inconveniences for volume operations.

-

Collapsible Rigid Box vs Folding Carton – Applications and Cost Implications

Folding cartons offer the lowest initial costs and simplest assembly but lack the premium presentation quality required for luxury applications. They work well for functional packaging but cannot match the perceived value enhancement provided by rigid alternatives. Material costs typically favor folding cartons, while presentation impact strongly favors rigid solutions. Application suitability varies significantly between these options. Luxury cosmetics, high-end electronics, and premium retail merchandise benefit from rigid construction, while everyday consumer goods may perform adequately with folding carton solutions. Cost analysis must include both unit pricing and total value impact on brand perception.

-

Evaluating Durability and Packaging Efficiency

Transit conditions significantly impact packaging performance, making durability assessment crucial for procurement decisions. High-quality collapsible rigid boxes maintain structural integrity through multiple handling cycles while providing adequate protection against moisture, impact, and compression forces encountered during shipping. Space-saving potential extends beyond initial shipping to include return logistics and storage efficiency. Boxes that maintain functionality through multiple assembly cycles offer enhanced value for reusable applications, while single-use scenarios focus primarily on initial performance and cost-effectiveness.

-

Cost Comparison and Long-Term Value Analysis

Total cost of ownership analysis reveals the true economic impact of packaging decisions, extending beyond unit pricing to encompass logistics costs, storage expenses, and brand value enhancement. The 20%-30% cost savings compared to standard collapsible alternatives often justify premium material selections for quality-conscious applications. Bulk order discounts and supplier pricing transparency enable accurate cost projections and budget planning. Suppliers offering clear pricing structures and volume-based incentives facilitate long-term procurement planning and relationship development that benefits both parties over time.

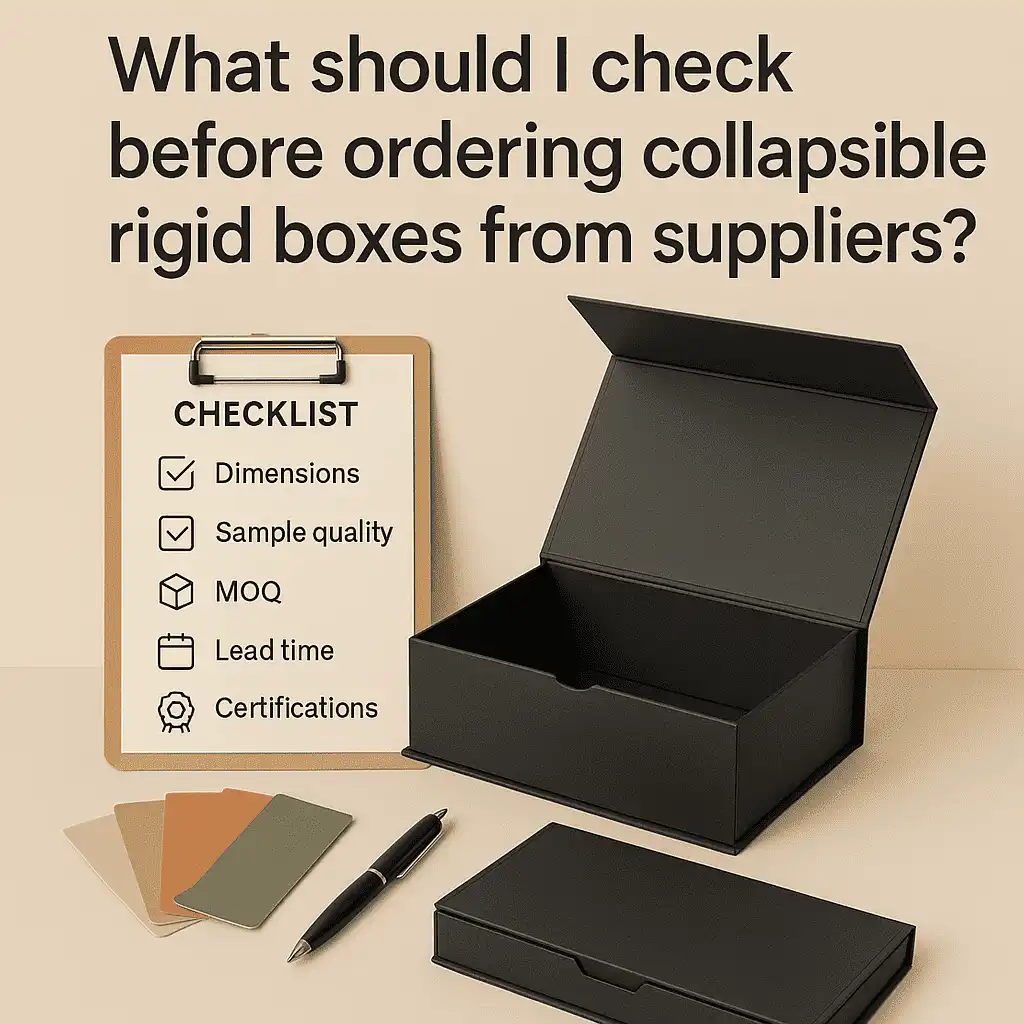

Step-by-Step Procurement Checklist Before Placing Your Order

Successful procurement requires systematic approach that addresses every aspect of the buying process. Following a comprehensive checklist reduces risks, prevents delays, and ensures optimal outcomes for your packaging requirements.

-

Define Your Packaging Requirements and Volume Needs

Product dimension analysis determines appropriate box sizes and structural requirements, ensuring optimal fit and protection. Consider height, width, depth, and weight specifications alongside presentation requirements and assembly complexity preferences. Volume projections influence supplier selection, pricing negotiations, and delivery scheduling.

-

Request Samples and Verify Material Quality

Physical samples provide crucial insights into material quality, construction integrity, and assembly processes that cannot be evaluated through specifications alone. Examine printing quality, surface finish consistency, fold mechanisms, and overall durability through hands-on testing that simulates actual use conditions.

-

Confirm Lead Times and Minimum Order Quantities (MOQs)

Production scheduling requires accurate lead time estimates and MOQ confirmation to ensure timely delivery and cost-effective ordering patterns. Advanced suppliers utilizing automated visual positioning production lines often provide shorter lead times and more flexible MOQ requirements than traditional manufacturers.

-

Review Payment Terms, Warranty, and After-Sales Service

Financial terms and service guarantees protect against procurement risks while establishing clear expectations for both parties. Comprehensive warranty coverage and responsive after-sales support demonstrate supplier confidence in their products and commitment to customer satisfaction.

-

Negotiate Customization and Packaging Solutions

Branding integration and customization options enhance market presence and product differentiation. Discuss printing specifications, surface treatments, structural modifications, and proprietary design elements that align with your brand requirements and market positioning goals.

About FetchingPrinting – Trusted Supplier of Collapsible Rigid Boxes

FetchingPrinting brings over two decades of industry expertise to collapsible rigid box manufacturing, operating since 1999 with comprehensive capabilities spanning design, production, and customer service. Our 35,000 square meter facility houses advanced machinery and serves over 1,000 loyal customers across multiple industries.

-

Product Range and Customization Capabilities

We offer proprietary collapsible rigid boxes in three patent-protected sizes tailored for magnetic gift box applications. Our Large size accommodates products 100-150mm in height, Medium suits 50-100mm applications, and Tiny handles 20-50mm requirements. Each design optimizes space efficiency while maintaining premium presentation quality. Material options include premium SBS C1S and C2S substrates, cost-effective CCNB, sustainable brown kraft, and luxury metallic finishes. Surface enhancement capabilities encompass hot foil stamping, UV coating, embossing, and specialized treatments that create distinctive visual and tactile experiences for your customers.

-

Commitment to Quality, Sustainability, and Customer Satisfaction

Our comprehensive certification portfolio includes ISO14001-2015 Environmental Management, ISO9001-2015 Quality Management, FSC, G7 Color Management, and Disney certification. These credentials demonstrate our commitment to operational excellence, environmental responsibility, and customer satisfaction across all business activities. Over ten packaging engineers with extensive professional experience support new material applications, structural development, artwork design, and process technology optimization. This expertise ensures innovative solutions that meet evolving market demands while maintaining cost-effectiveness and production efficiency.

-

How We Support Your Procurement Process?

Our streamlined ordering process begins with demand consultation where customers receive expert guidance on optimal packaging solutions. Solution design follows, involving comprehensive content coordination between business managers and clients to ensure precise requirement understanding. Professional implementation includes sample production according to customer specifications, allowing detailed confirmation before full production commitment. Our automated visual positioning production lines ensure short production times and stable quality throughout manufacturing, while dedicated account management provides consistent communication and project oversight.

Frequently Asked Questions

Q1: How long does it typically take to manufacture collapsible rigid boxes?

A: Production times vary based on order complexity and customization requirements. Our automated visual positioning production lines enable shorter manufacturing cycles compared to traditional methods, typically ranging from 7-15 business days for standard orders. Complex customizations or large volumes may require additional time, which we communicate clearly during the quotation process.

Q2: Are eco-friendly collapsible rigid boxes more expensive than traditional ones?

A: Eco-friendly options like FSC-certified materials and recyclable substrates may carry modest premium pricing, typically 5-15% above standard alternatives. However, the long-term value includes enhanced brand reputation, regulatory compliance, and consumer preference alignment that often justifies the investment. Many clients find that sustainability features support premium positioning and customer loyalty.

Q3: Can I request custom printing and design modifications for my order?

A: Absolutely. We specialize in comprehensive customization including structural modifications, surface treatments, and branding integration. Our capabilities include hot foil stamping, UV coating, embossing, frosted touch finishes, and specialized printing techniques. Our R&D team collaborates closely with clients to develop solutions that meet specific requirements while maintaining cost-effectiveness and production efficiency.

Partner with FetchingPrinting for Premium Collapsible Rigid Box Solutions

Elevate your packaging strategy with FetchingPrinting's innovative collapsible rigid box solutions that deliver superior cost savings and premium presentation quality. Our proprietary designs save over 60% in shipping and storage costs while maintaining the luxury appeal your brand demands. As a leading collapsible rigid box manufacturer with 25 years of industry expertise, we understand the unique challenges facing procurement managers in today's competitive marketplace.

Our comprehensive approach combines cutting-edge manufacturing technology with sustainable material options and flexible customization capabilities. From initial consultation through final delivery, our team of packaging engineers ensures your specifications are met precisely and efficiently. Whether you need Large, Medium, or Tiny configurations for magnetic gift boxes, our patent-protected designs provide competitive advantages that enhance your market position.

Ready to optimize your packaging costs while elevating brand presentation? Contact us at public@fetchingprinting.com to request samples and receive a personalized consultation. Discover how FetchingPrinting's expertise, advanced manufacturing capabilities, and commitment to customer satisfaction can transform your packaging operations and drive business growth.

Conclusion

Successful collapsible rigid box procurement requires comprehensive supplier evaluation encompassing reputation verification, manufacturing capabilities assessment, and customization options analysis. Key considerations include material quality, certification compliance, cost-effectiveness, and sustainability alignment with corporate goals. Systematic evaluation using structured checklists reduces procurement risks while ensuring optimal packaging solutions.

The substantial cost savings potential—exceeding 60% compared to traditional rigid boxes—makes collapsible alternatives increasingly attractive for volume operations. However, balancing cost efficiency with quality requirements demands careful supplier selection and clear requirement definition. Working with experienced manufacturers offering proprietary designs, comprehensive certifications, and dedicated support ensures successful outcomes for B2B procurement initiatives.

References

1. Smith, J. (2023). "Packaging Cost Optimization in Modern Supply Chains." International Journal of Packaging Technology, Vol. 15, No. 3, pp. 45-62.

2. Chen, L. & Rodriguez, M. (2024). "Sustainable Packaging Materials and Their Impact on Brand Value." Green Business Quarterly, Issue 2, pp. 28-41.

3. Anderson, K. (2023). "Collapsible Packaging Solutions: Engineering and Economic Analysis." Packaging Engineering Review, Vol. 8, No. 4, pp. 112-128.

4. Thompson, R. (2024). "B2B Procurement Best Practices for Packaging Solutions." Supply Chain Management Today, March Edition, pp. 76-89.

5. Williams, D. & Park, S. (2023). "Quality Management Systems in Packaging Manufacturing." Industrial Quality Standards Journal, Vol. 12, No. 7, pp. 203-218.

6. Johnson, A. (2024). "Cost-Benefit Analysis of Rigid vs. Collapsible Packaging Systems." Packaging Economics Review, Vol. 9, No. 1, pp. 34-49.