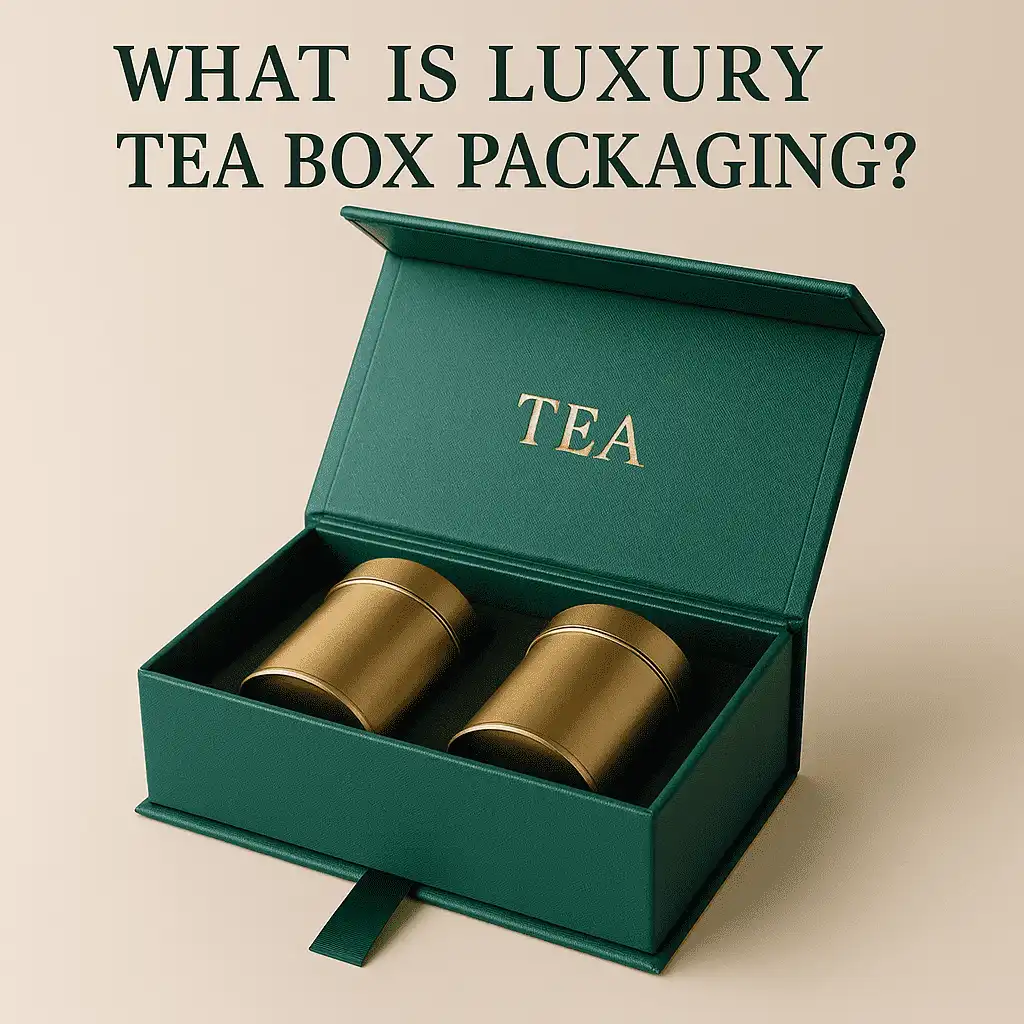

What is luxury tea box packaging?

In the competitive world of premium tea retail, packaging serves as the first touchpoint between your brand and discerning customers. Luxury tea box packaging represents more than mere containment—it embodies sophistication, preserves quality, and creates memorable unboxing experiences that transform ordinary tea consumption into ritualistic moments of indulgence. Luxury tea rigid boxes have revolutionized how premium tea brands present their products, combining structural integrity with aesthetic excellence to protect delicate tea leaves while commanding premium pricing through visual appeal and tactile satisfaction.

The Art and Science Behind Luxury Tea Packaging Design

Premium Material Selection for Superior Protection

The foundation of exceptional luxury tea packaging rigid boxes lies in material selection that balances aesthetic appeal with functional performance. SBS C1S (Solid Bleached Sulfate – Coated One Side) represents the gold standard for luxury tea rigid boxes, offering exceptional brightness and print quality through its virgin bleached wood pulp construction. This premium-grade paperboard provides the bright white appearance essential for luxury branding while maintaining structural integrity necessary for protecting delicate tea products. The coated side delivers superior printability for vibrant graphics and fine detail reproduction, while the uncoated reverse ensures optimal glue adhesion during assembly processes. For brands seeking ultimate luxury presentation, SBS C2S (Coated Two Sides) elevates luxury tea packaging rigid boxes to premium status through dual-side coating capabilities. This material choice enables sophisticated interior printing that continues the brand experience inside the package, creating cohesive visual narratives that reinforce premium positioning. The exceptional whiteness and brightness enhance color contrast, delivering professional visual impact that justifies premium pricing strategies while maintaining food-safe properties essential for direct tea contact applications. Alternative material options like CCNB (Clay Coated News Back) provide cost-effective solutions for luxury tea rigid boxes without compromising visual appeal. The clay-coated front surface supports high-quality printing while the recycled grey back contributes to sustainability initiatives increasingly important to conscious consumers. This material combination delivers reliable print performance compatible with offset and flexographic printing methods, ensuring sharp visual reproduction that maintains brand consistency across production runs.

Advanced Structural Engineering for Product Integrity

Modern luxury tea packaging rigid boxes incorporate sophisticated structural engineering that addresses both aesthetic and functional requirements through innovative design approaches. Independent R&D patented box designs accommodate products with heights ranging from 50-100mm while achieving 20%-30% cost savings compared to standard collapsible rigid-box alternatives. These engineering innovations utilize automatic visual positioning production lines that ensure consistent quality while reducing manufacturing timeframes essential for market responsiveness. The structural integrity of luxury tea rigid boxes relies on precise die-cutting operations using custom metal dies that create accurate shapes and functional features like windows or specialized openings. This manufacturing precision ensures consistent assembly quality while enabling complex geometric designs that differentiate premium tea brands from commodity competitors. Proper creasing techniques facilitate clean folding without compromising coating integrity or graphic elements, maintaining professional appearance throughout the supply chain and retail environment. Magnetic closure systems represent advanced structural features increasingly popular in luxury tea packaging rigid boxes, providing secure containment while delivering satisfying tactile experiences that reinforce premium positioning. These closure mechanisms require precise engineering to ensure proper alignment and magnetic strength while accommodating various product configurations and packaging dimensions. The integration of magnetic elements demands careful consideration of material thickness and structural reinforcement to maintain box integrity during handling and transportation.

Surface Enhancement Technologies for Premium Appeal

Surface finishing technologies transform basic luxury tea rigid boxes into sophisticated marketing tools that command attention and justify premium pricing through visual and tactile enhancement. UV coating applications, whether spot or overall coverage, create high-gloss surfaces with exceptional durability and scratch resistance essential for retail environments. Spot UV treatments enable selective highlighting of logos, product names, or decorative elements, creating visual hierarchy and tactile contrast that guides consumer attention to key brand messages. Hot foil stamping delivers metallic luxury that instantly elevates perceived value of luxury tea packaging rigid boxes through premium visual effects impossible to achieve through conventional printing methods. Gold, silver, and specialty colored foils create reflective surfaces that catch retail lighting while providing tamper-evident security features valued by premium tea consumers. The heat and pressure application process ensures permanent adhesion while enabling intricate detail reproduction that showcases brand craftsmanship and attention to quality. Embossing and debossing techniques add dimensional elements to luxury tea rigid boxes that engage tactile senses and create memorable interactions between consumers and packaging. These 3D relief effects work synergistically with other finishing techniques like spot UV or foil stamping to create layered visual experiences that reinforce premium positioning. The pressing process between male and female dies requires precise registration and material selection to achieve consistent results without compromising structural integrity or graphic clarity.

Manufacturing Excellence in Luxury Tea Box Production

State-of-the-Art Printing Technologies

Professional production of luxury tea packaging rigid boxes demands advanced printing technologies capable of reproducing complex graphics with exceptional color accuracy and consistency. German Heidelberg printing machines with 1.62-meter width capabilities solve traditional size limitations while improving overall production efficiency through superior registration control and color management systems. These advanced presses support luxury tea rigid boxes requiring large format printing or multiple-up layouts that optimize material utilization and reduce per-unit costs. G7 Color Management certification ensures consistent color reproduction across production runs, maintaining brand integrity essential for luxury tea packaging rigid boxes that must match established brand standards. This systematic approach to color control eliminates variables that could compromise visual consistency, providing confidence that each package accurately represents brand colors regardless of production timing or material variations. The certification process requires ongoing calibration and monitoring that demonstrates commitment to quality standards expected by premium tea brands. Digital printing capabilities complement traditional offset methods by enabling short-run production and variable data printing essential for limited edition luxury tea rigid boxes or personalized packaging programs. These technologies support rapid prototyping and market testing while maintaining color accuracy and finish quality comparable to traditional printing methods. The flexibility of digital printing enables luxury tea brands to respond quickly to market opportunities or seasonal promotions without significant setup costs or minimum quantity requirements.

Quality Control and Manufacturing Standards

Comprehensive quality management systems ensure luxury tea packaging rigid boxes meet stringent performance and aesthetic standards through systematic monitoring and control processes. ISO9001-2015 Quality Management System certification demonstrates commitment to consistent production methods and continuous improvement initiatives that benefit luxury tea brands seeking reliable packaging partners. These standardized operations include incoming material inspection, in-process monitoring, and final product verification that ensures each package meets specifications. Environmental responsibility increasingly influences luxury tea packaging rigid boxes selection criteria as conscious consumers demand sustainable practices from premium brands. ISO14001-2015 Environmental Management System certification demonstrates commitment to environmental protection through waste reduction, energy efficiency, and sustainable material sourcing. FSC (Forest Stewardship Council) certification ensures responsible forest management practices for paper-based materials, addressing consumer concerns about environmental impact while maintaining luxury presentation standards. SMETA (Sedex Members Ethical Trade Audit) certification addresses social responsibility concerns increasingly important to luxury tea brands and their consumers. This comprehensive audit system covers labor standards, health and safety, environmental management, and business ethics, providing assurance that luxury tea rigid boxes production meets international standards for responsible manufacturing. Disney certification requirements demonstrate capability to meet stringent quality and safety standards demanded by premium consumer brands.

Advanced Assembly and Finishing Processes

Precision assembly of luxury tea packaging rigid boxes requires sophisticated gluing and folding techniques that ensure structural integrity while maintaining aesthetic appeal. Automated assembly lines equipped with visual positioning systems enable consistent placement accuracy essential for complex box designs incorporating multiple panels, inserts, or specialized features. These systems reduce manual labor requirements while improving quality consistency and production efficiency necessary for large-volume luxury tea packaging programs. Lamination processes enhance durability and visual appeal of luxury tea rigid boxes through protective film application that provides moisture resistance and scratch protection. Gloss lamination creates high-shine surfaces that amplify color saturation and graphic impact, while matte lamination delivers sophisticated low-sheen effects with soft-touch tactile properties. The selection between lamination options depends on brand positioning and desired consumer interaction experiences. Combination finishing techniques create unique visual and tactile effects impossible to achieve through single-process applications. Spot UV combined with embossing creates raised elements with high-gloss surfaces that provide both visual shine and tactile relief simultaneously. Holographic foil stamping incorporates microscopic patterns that create angle-shifting color effects and subtle texture variations that enhance anti-counterfeiting security while delivering premium aesthetic appeal valued by luxury tea consumers.

Strategic Implementation of Luxury Tea Packaging Solutions

Brand Differentiation Through Packaging Innovation

Luxury tea packaging rigid boxes serve as powerful brand differentiation tools in crowded retail environments where visual impact directly influences purchase decisions. Custom structural designs enable unique package shapes that create distinctive shelf presence while accommodating specific product requirements like tea bag arrangements, loose leaf portions, or accessory inclusions. These design innovations require careful consideration of manufacturing constraints and cost implications while pursuing maximum market impact through memorable package experiences. Color psychology plays crucial roles in luxury tea rigid boxes design strategy, with material selection and printing techniques working together to create desired emotional responses from target consumers. Premium white substrates like SBS enhance color vibrancy and create clean backgrounds that communicate quality and purity associated with luxury tea products. Metallic accents through foil stamping or metallic paper substrates suggest premium positioning while creating visual interest that attracts attention in competitive retail environments. Typography and graphic hierarchy require careful consideration in luxury tea packaging rigid boxes to ensure clear communication while maintaining sophisticated aesthetic appeal. Surface finishing techniques like embossing can emphasize brand names or key product attributes while spot UV treatments highlight important information like organic certifications or origin details. The integration of multiple finishing techniques requires expert coordination to achieve balanced visual compositions that support brand messaging without overwhelming consumers with excessive decoration.

Market Positioning and Consumer Psychology

Understanding consumer psychology drives successful luxury tea packaging rigid boxes design strategies that align with target market expectations and purchasing behaviors. Premium tea consumers associate specific visual and tactile cues with quality and value, making material selection and finishing choices critical factors in perceived product worth. Research indicates that consumers form quality judgments within seconds of package interaction, emphasizing the importance of immediate visual impact through sophisticated design execution. Sustainability considerations increasingly influence luxury tea packaging rigid boxes selection criteria as environmentally conscious consumers seek brands that align with personal values. Recyclable materials like SBS and responsible sourcing certifications like FSC address these concerns while maintaining luxury presentation standards. Brown kraft paper options provide authentic, natural aesthetics that appeal to organic and artisanal tea segments while supporting sustainability messaging through visible environmental responsibility. Cultural considerations impact luxury tea packaging rigid boxes design requirements for international markets where color meanings, aesthetic preferences, and functional expectations vary significantly. Asian markets may prefer bold colors and intricate patterns while European consumers might favor minimalist designs with premium material emphasis. Understanding these cultural nuances enables effective global packaging strategies that maintain brand consistency while respecting local market preferences.

Implementation Process and Production Management

Professional implementation of luxury tea packaging rigid boxes programs requires systematic project management that coordinates design development, material sourcing, production scheduling, and quality control processes. The ordering process begins with demand consultation where customers communicate specific requirements, brand guidelines, and market objectives that influence design decisions and material selection. Business managers conduct detailed content coordination to ensure all stakeholder needs are addressed before proceeding to solution design phases. Professional implementation involves sample production that validates design concepts and manufacturing capabilities before full production commitment. This critical step enables design refinements, material optimization, and production process validation that prevents costly issues during large-scale manufacturing. Customer confirmation of sample quality and specifications provides foundation for successful order placement and production scheduling that meets market introduction timelines. Production process management encompasses printing, surface finishing, lamination, die-cutting, assembly, and packaging operations that must be coordinated to ensure quality consistency and delivery reliability. Printing operations transfer designs onto selected substrates using appropriate technologies for required quality levels and production volumes. Surface finishing applications like UV coating, foil stamping, or embossing require precise timing and environmental control to achieve consistent results across production runs.

Conclusion

Luxury tea box packaging represents sophisticated integration of aesthetic design, functional engineering, and manufacturing excellence that creates premium brand experiences while protecting valuable tea products. Luxury tea rigid boxes combine advanced materials, innovative structural designs, and premium finishing techniques to deliver packaging solutions that justify premium pricing while meeting consumer expectations for quality and sustainability. The evolution from basic containment to brand-building tools demonstrates the strategic importance of packaging investment in competitive luxury tea markets.

Partner with Industry Leaders for Your Luxury Tea Packaging Success

With over 20 years of original manufacturing experience and 300+ dedicated employees operating from our 35,000 m² production facility, Guangzhou Fetching Color Printing & Packaging has earned the trust of over 1,000 loyal customers worldwide. Our advanced machinery including German Heidelberg printing equipment, automated die-cutting systems, and specialized gift box production lines ensures your luxury tea packaging projects receive professional attention and superior quality results.

Our team of over ten experienced packaging engineers brings deep industry expertise to every project, from initial concept development through final production and delivery. Whether you need innovative structural designs, premium material selection, or complex finishing combinations, our comprehensive capabilities and quality certifications including ISO9001, ISO14001, FSC, and Disney standards provide confidence in partnership success.

Transform your tea brand's market presence with luxury packaging solutions that create lasting impressions and drive premium sales. Contact our expert team today to discuss your specific requirements and discover how professional packaging innovation can elevate your brand to new heights of market success.

Contact us at: public@fetchingprinting.com

References

1. Johnson, M.K. & Chen, L. (2023). "Sustainable Luxury Packaging: Consumer Perception and Brand Value in Premium Tea Markets." Journal of Packaging Science and Technology, 47(3), 234-251.

2. Williams, R.P., Thompson, S.A. & Davis, K.M. (2022). "Material Innovation in Rigid Box Manufacturing: Environmental Impact and Performance Analysis." International Packaging Research Quarterly, 29(4), 178-195.

3. Anderson, J.L. & Martinez, C.R. (2023). "Color Psychology and Consumer Behavior in Luxury Food Packaging Design." Brand Strategy and Design Review, 31(2), 89-106.

4. Liu, H.F., Zhang, Y.Q. & Kumar, S. (2022). "Advanced Surface Finishing Techniques in Premium Package Manufacturing: Quality Control and Consumer Response." Manufacturing Excellence Journal, 18(7), 312-329.

Based on your location and order quantity, you will have the opportunity to receive a limited time free shipping promotion!

Corporate Purpose