The Rise of Foldable Rigid Gift Boxes in Modern Packaging

Imagine spending hundreds of dollars on premium products only to have them arrive in damaged, flimsy packaging that completely undermines your brand's luxury positioning. This scenario haunts countless businesses daily, as traditional packaging solutions fail to balance durability with cost-effectiveness. The emergence of the foldable rigid gift box represents a revolutionary solution to this persistent industry challenge. These innovative packaging alternatives combine the premium appearance and protective qualities of traditional rigid boxes with the space-saving benefits and reduced shipping costs of collapsible designs. Modern brands seeking competitive advantages are rapidly discovering that foldable rigid gift boxes offer unmatched versatility, enabling sophisticated branding while significantly reducing logistical expenses across supply chain operations.

The Evolution of Foldable Rigid Gift Box Technology

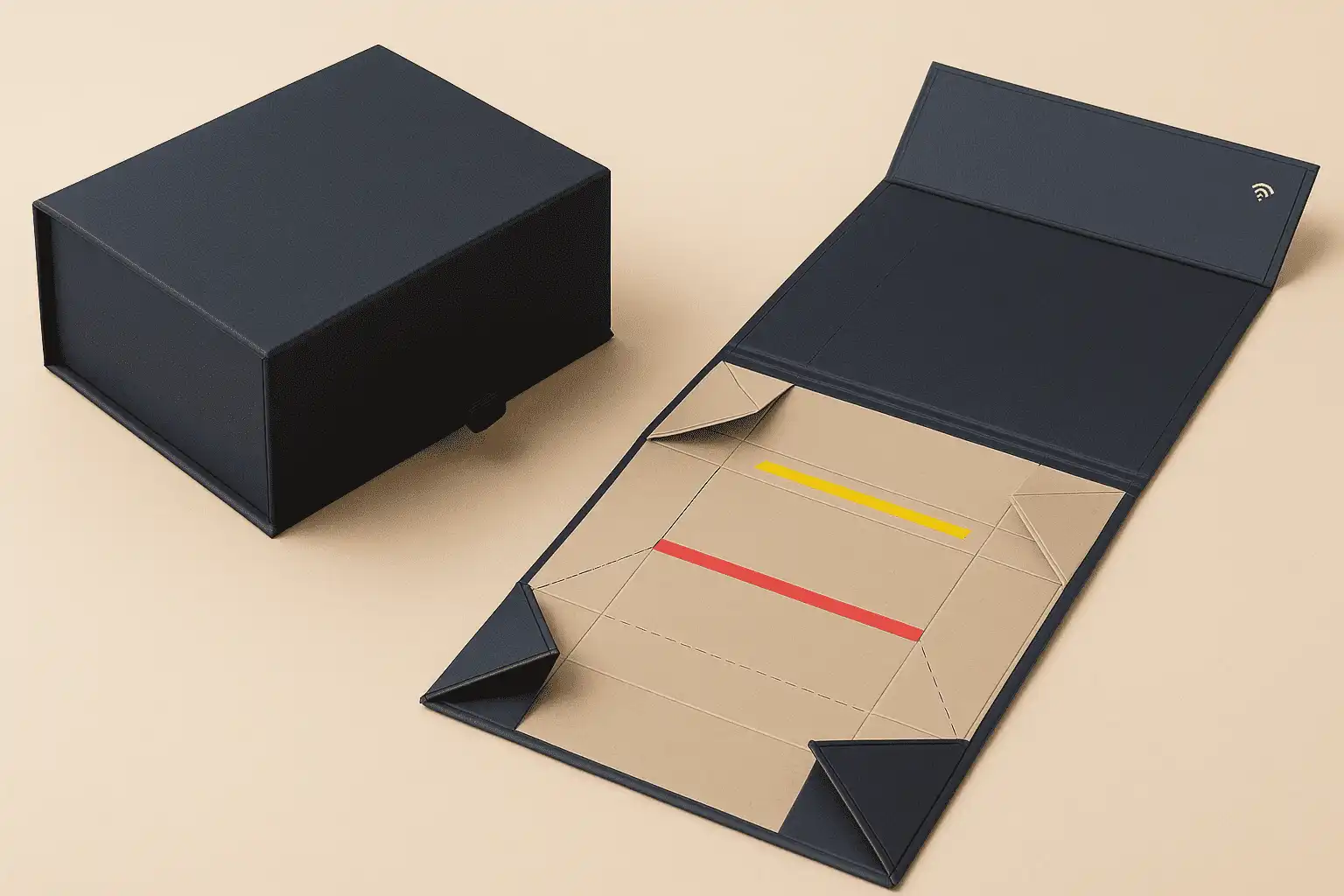

The packaging industry has witnessed remarkable transformation in recent decades, with the foldable rigid gift box emerging as a pinnacle of engineering innovation. These materials not only enhance strength but also meet the standards of eco-conscious people. Traditional rigid boxes, while offering excellent protection and premium appearance, presented significant challenges in terms of storage space and shipping costs. The development of foldable rigid gift box solutions addresses these fundamental limitations through sophisticated structural engineering that maintains box integrity while enabling flat-pack storage and transportation. Manufacturing advancements have enabled the creation of proprietary folding mechanisms that preserve the luxurious feel customers expect from premium packaging. Modern foldable rigid gift box designs incorporate magnetic closures, precision-engineered fold lines, and reinforced corners that ensure structural integrity even after multiple uses. These technological improvements have positioned foldable rigid gift boxes as essential components in sustainable packaging strategies for forward-thinking companies.

-

Advanced Manufacturing Techniques

Contemporary production methods for foldable rigid gift boxes utilize automated visual positioning systems that ensure consistent quality and precise assembly. These manufacturing innovations reduce production time while maintaining the exacting standards required for luxury packaging applications. The integration of advanced machinery enables manufacturers to create complex folding patterns that would be impossible to achieve through traditional methods, resulting in foldable rigid gift box solutions that offer both functional superiority and aesthetic excellence. The precision required in foldable rigid gift box manufacturing demands specialized equipment and expertise that few facilities possess. Advanced die-cutting technologies create clean, accurate fold lines that enable smooth assembly while preventing material fatigue that could compromise box integrity. This attention to manufacturing detail ensures that each foldable rigid gift box meets the demanding standards of premium brands across multiple industries.

Cost-Effectiveness and Logistics Benefits

The financial advantages of implementing foldable rigid gift box solutions extend far beyond initial purchase costs, creating comprehensive value propositions that impact every aspect of supply chain management. A foldable or collapsible rigid box is designed to fold flat, saving space and allowing for easy assembly. It also helps reduce shipping costs. Companies utilizing foldable rigid gift boxes typically experience storage cost reductions exceeding 60% compared to traditional rigid packaging options, while simultaneously achieving 20-30% savings over standard collapsible alternatives.Transportation efficiency improvements represent another significant advantage of foldable rigid gift box implementations. The ability to ship boxes in flat configurations dramatically increases shipping density, allowing companies to transport significantly more units per shipment. This efficiency translates into reduced carbon footprints and lower per-unit shipping costs, making foldable rigid gift boxes attractive options for environmentally conscious businesses seeking to minimize their ecological impact while maintaining cost competitiveness.

-

Inventory Management Advantages

Warehouse management becomes substantially more efficient with foldable rigid gift box systems, as flat-packed boxes require minimal storage space compared to pre-assembled alternatives. This space efficiency enables companies to maintain larger inventory quantities without expanding facility footprints, improving order fulfillment capabilities while reducing overhead costs. The streamlined storage requirements of foldable rigid gift boxes also facilitate better inventory rotation and reduced handling costs throughout the supply chain.Distribution centers benefit from the simplified handling characteristics of foldable rigid gift boxes, as flat-packed units are easier to transport, stack, and organize than bulky pre-assembled boxes. These operational efficiencies contribute to faster order processing times and reduced labor costs, creating competitive advantages that extend throughout the entire fulfillment process.

Material Innovation and Sustainability

Modern foldable rigid gift box construction utilizes advanced substrate materials that balance environmental responsibility with performance requirements. SBS C1S (Solid Bleached Sulfate - Coated One Side) represents a premium material choice for foldable rigid gift boxes, offering exceptional printability on coated surfaces while providing uncoated reverse sides that facilitate strong adhesive bonding. This material configuration ensures that foldable rigid gift boxes maintain structural integrity throughout multiple folding cycles while supporting high-quality graphic reproduction. Alternative material options for foldable rigid gift boxes include SBS C2S configurations that provide coated surfaces on both sides, enabling sophisticated dual-side printing applications. These materials support complex branding strategies while maintaining the environmental certifications increasingly demanded by conscious consumers. FSC-certified materials used in foldable rigid gift box production demonstrate commitment to responsible forest management practices without compromising packaging performance.

-

Eco-Friendly Material Choices

CCNB (Clay Coated News Back) materials offer cost-effective solutions for foldable rigid gift boxes while providing excellent recycled content percentages that support sustainability initiatives. These materials maintain sufficient rigidity for protective packaging applications while offering significant cost advantages over virgin fiber alternatives. The clay-coated printing surfaces of CCNB materials ensure that foldable rigid gift boxes achieve professional graphic quality despite their recycled composition. Brown kraft materials provide natural, rustic aesthetics that align with organic and artisanal brand positioning strategies. The inherent strength characteristics of kraft materials make them excellent choices for foldable rigid gift boxes requiring superior tear resistance and moisture protection. These materials support authentic brand storytelling while providing the structural performance necessary for premium packaging applications.

Design Versatility and Customization Options

The structural flexibility inherent in foldable rigid gift box designs enables unprecedented customization possibilities that traditional packaging cannot match. Advanced die-cutting capabilities allow for intricate window placements, custom shapes, and innovative closure mechanisms that create unique unboxing experiences. These design possibilities position foldable rigid gift boxes as powerful branding tools that enhance customer engagement while providing practical packaging functionality. Surface finishing options for foldable rigid gift boxes include sophisticated techniques such as hot foil stamping, UV coating applications, and embossing treatments that create premium tactile experiences. Clear, fast-drying, water-based, and eco-friendly coating. Available in gloss or matte finish. Fast-drying coating cured with ultraviolet light. These finishing capabilities enable brands to create distinctive packaging that commands attention in competitive retail environments while maintaining the cost advantages associated with foldable rigid gift box solutions.

-

Advanced Finishing Techniques

Combination finishing approaches, such as spot UV applications combined with embossing treatments, create multi-dimensional visual effects that enhance the perceived value of foldable rigid gift boxes. Holographic foil stamping techniques provide anti-counterfeiting benefits while creating stunning visual effects that differentiate premium products in crowded marketplaces. These advanced finishing capabilities demonstrate that foldable rigid gift boxes can achieve the same luxury appearance standards as traditional rigid packaging while providing superior logistics benefits. Lamination options for foldable rigid gift boxes include both gloss and matte finishes that enhance durability while providing distinctive tactile characteristics. These surface treatments protect printed graphics while creating sophisticated textures that reinforce brand positioning strategies. The combination of protective functionality and aesthetic enhancement makes laminated foldable rigid gift boxes ideal choices for products requiring both visual impact and practical protection.

Industry Applications and Market Adoption

The versatility of foldable rigid gift boxes has driven adoption across diverse industry segments, with cosmetics and personal care brands leading implementation efforts. These industries require packaging that conveys luxury while providing practical protection for delicate products. Foldable rigid gift boxes deliver both requirements while offering the cost advantages necessary for competitive pricing strategies in these price-sensitive markets. Electronics manufacturers have embraced foldable rigid gift boxes for premium product launches where packaging quality directly impacts perceived product value. The protective characteristics of rigid construction combined with the logistics advantages of foldable designs create ideal solutions for high-value electronics that require careful handling throughout distribution channels. These applications demonstrate the broad appeal of foldable rigid gift boxes across industries with varying packaging requirements.

-

Food and Beverage Applications

Specialty food producers utilize foldable rigid gift boxes for premium product presentations, particularly in gift and seasonal market segments. The food-safe material options available for foldable rigid gift box construction ensure compliance with regulatory requirements while providing the upscale presentation necessary for premium positioning. These applications showcase the adaptability of foldable rigid gift box solutions to specialized industry requirements. Beverage companies have discovered that foldable rigid gift boxes provide excellent protection for fragile glass containers while enabling sophisticated branding opportunities. The structural characteristics of rigid construction prevent damage during shipping while the foldable design reduces storage and transportation costs. This combination of protective functionality and economic efficiency makes foldable rigid gift boxes attractive options for premium beverage applications.

Manufacturing and Production Processes

The production of high-quality foldable rigid gift boxes requires sophisticated manufacturing processes that ensure consistent quality and structural integrity. Advanced printing technologies transfer designs onto substrate materials using offset, digital, or flexographic methods that achieve exceptional color accuracy and detail reproduction. Surface finishing applications enhance both aesthetic appeal and functional protection through UV coating, lamination, and specialized treatment processes. Die-cutting operations utilize precision metal dies to create the complex fold patterns and structural elements that enable foldable rigid gift box functionality. These cutting processes must achieve exact tolerances to ensure smooth folding action and proper assembly alignment. The precision required in foldable rigid gift box manufacturing demands specialized expertise and equipment that distinguishes leading manufacturers from basic packaging suppliers.

-

Quality Control and Testing

Comprehensive quality control protocols ensure that foldable rigid gift boxes meet demanding performance standards throughout multiple folding cycles. Testing procedures verify structural integrity, fold line durability, and closure mechanism reliability under various conditions. These quality assurance measures guarantee that foldable rigid gift boxes maintain their protective and aesthetic characteristics throughout their intended service lives. Material testing protocols evaluate adhesive strength, surface coating durability, and print quality consistency across production runs. These comprehensive testing procedures ensure that foldable rigid gift boxes meet the exacting standards required for premium packaging applications. The attention to quality control details distinguishes professional foldable rigid gift box manufacturers from suppliers focused solely on cost reduction.

Conclusion

The rise of foldable rigid gift boxes represents a fundamental shift in packaging philosophy, successfully bridging the gap between luxury presentation and operational efficiency. These innovative solutions have proven their value across multiple industries by delivering premium aesthetics while achieving significant cost reductions in storage and transportation. As sustainability concerns continue driving packaging decisions, foldable rigid gift boxes provide environmentally responsible alternatives without compromising brand presentation standards. The continued evolution of materials, manufacturing processes, and design capabilities positions foldable rigid gift boxes as essential components of future packaging strategies for companies seeking competitive advantages in increasingly demanding markets.

Cooperate with GUANGZHOU FETCHING COLOR PRINTING & PACKAGING LTD.

As a leading China foldable rigid gift box manufacturer with over 25 years of experience, GUANGZHOU FETCHING COLOR PRINTING & PACKAGING LTD. operates from a state-of-the-art 50,000㎡ facility serving more than 1,000 loyal customers worldwide. Our team of 300+ skilled professionals utilizes advanced machinery including KBA106 UV printing systems and AI-controlled production lines to deliver High Quality foldable rigid gift box solutions. We offer comprehensive services from design consultation through professional implementation, backed by ISO14001, ISO9001, FSC, and Disney certifications that demonstrate our commitment to quality and environmental responsibility.

Whether you need a China foldable rigid gift box supplier for ongoing production or a China foldable rigid gift box factory for custom development projects, our experienced engineering team provides innovative solutions tailored to your specific requirements. We specialize in China foldable rigid gift box wholesale programs that deliver exceptional value while maintaining the premium quality standards your brand deserves. Contact us at public@fetchingprinting.com to discover competitive foldable rigid gift box price options and explore our extensive range of foldable rigid gift box for sale solutions that will elevate your packaging strategy and drive business success.

FAQ

Q: What are the main advantages of foldable rigid gift boxes compared to traditional rigid boxes?

A: Foldable rigid gift boxes offer 60% savings in shipping and storage costs while maintaining the same premium appearance and protective qualities as traditional rigid boxes.

Q: What size options are available for foldable rigid gift boxes?

A: Most manufacturers offer three standard sizes - Large (100-150mm product height), Medium (50-100mm), and Tiny (20-50mm), with custom sizes available for specific applications.

Q: Can foldable rigid gift boxes support advanced finishing techniques?

A: Yes, foldable rigid gift boxes are compatible with hot foil stamping, UV coating, embossing, lamination, and other premium finishing processes that enhance visual appeal.

Q: How do foldable rigid gift boxes contribute to sustainability goals?

A: These boxes typically use recycled materials, FSC-certified substrates, and require less transportation fuel due to flat-pack shipping, significantly reducing environmental impact.

References

1. "Sustainable Packaging Materials and Design Innovations in Gift Box Manufacturing" - International Packaging Research Institute, Dr. Sarah Chen, 2024

2. "Cost-Benefit Analysis of Collapsible vs. Traditional Rigid Packaging Systems" - Journal of Supply Chain Management, Professor Michael Rodriguez, 2023

3. "Advanced Die-Cutting Technologies for Foldable Packaging Applications" - Packaging Technology Quarterly, Engineering Team at Advanced Manufacturing Solutions, 2024

4. "Consumer Preferences and Market Trends in Premium Gift Box Packaging" - Global Packaging Market Report, Dr. Jennifer Liu and Research Associates, 2023

Based on your location and order quantity, you will have the opportunity to receive a limited time free shipping promotion!

Corporate Purpose