How To Choose Collapsible gift boxes Manufacturer?

Selecting the right manufacturer for collapsible gift boxes is a crucial decision that can significantly impact your product presentation, customer satisfaction, and overall business success. With countless manufacturers claiming to offer the best solutions, navigating this landscape requires careful consideration of multiple factors. This comprehensive guide will walk you through the essential elements to evaluate when choosing a reliable Collapsible Gift Boxes manufacturer, ensuring you make an informed decision that aligns with your specific packaging needs and business objectives.

Evaluating Manufacturer Credentials and Capabilities

When searching for the perfect partner to produce your collapsible gift boxes, examining a manufacturer's credentials and production capabilities should be your first priority. This evaluation process helps ensure your chosen partner can deliver the quality and consistency your brand deserves.

Manufacturing Experience and Industry Reputation

A manufacturer's longevity in the packaging industry often translates to accumulated expertise and refined production processes. Companies like Fetching Printing, established in 1999 with over 20 years of experience, demonstrate a proven track record of adapting to industry changes while maintaining quality standards. When evaluating potential partners for your Collapsible Gift Boxes, investigate their portfolio of past projects and client testimonials. Experienced manufacturers typically have overcome various production challenges and developed systematic approaches to quality control. Their established presence also suggests financial stability and reliability—critical factors for forming long-term business relationships. Additionally, manufacturers with extensive experience often possess deeper insights into material selection, structural design optimization, and finishing techniques specifically for collapsible gift boxes, resulting in superior end products that stand out in the marketplace.

Production Capacity and Advanced Equipment

The scale and technological sophistication of a manufacturer's production facility directly impacts their ability to handle your orders efficiently. When selecting a Collapsible Gift Boxes supplier, consider their facility size and equipment inventory. Premium manufacturers typically invest in state-of-the-art machinery that enhances precision and consistency. For instance, Fetching Printing operates on 30,000m² of land with a 50,000m² production plant equipped with advanced machinery including KBA106-(9+1) UV printing machines, Heidelberg XL162-6L printing machines, and specialized AI gift box production lines. This extensive capacity enables them to handle large-volume orders while maintaining quality control. Modern equipment also translates to better color accuracy, sharper details, and more consistent finishing across your entire order of collapsible gift boxes. Furthermore, manufacturers with automated visual positioning box production lines can significantly reduce production times—delivering in just 15-20 days—while ensuring each box meets precise structural and visual specifications, a critical factor for premium packaging.

Research and Development Capabilities

Innovation in packaging design can give your products a competitive edge in the marketplace. Forward-thinking Collapsible Gift Boxes manufacturers invest substantially in research and development departments. Look for manufacturers with dedicated engineering teams that specialize in packaging structure development, new material applications, and process technology innovations. These teams can transform conventional collapsible gift boxes into distinctive packaging solutions that enhance brand recognition and consumer experience. For example, manufacturers with independent R&D capabilities often develop patented box structures that offer unique advantages—such as Fetching's patented collapsible rigid-boxes suitable for magnetic gift boxes with product heights of 50-100mm, which save 20-30% in costs compared to standard options. Additionally, strong R&D teams can provide valuable consultation during the design phase, helping identify potential structural weaknesses or suggesting innovative features that improve functionality while maintaining aesthetic appeal of your collapsible gift boxes. This collaborative approach often results in packaging solutions that not only look impressive but also perform exceptionally well throughout the distribution chain.

Quality Assurance and Compliance Standards

Quality consistency and regulatory compliance form the foundation of successful packaging partnerships. In today's environmentally conscious and quality-driven market, these factors deserve thorough scrutiny when selecting your collapsible gift box manufacturer.

Certification Systems and Quality Control Processes

Reputable manufacturers demonstrate their commitment to quality and standards compliance through recognized certifications. When evaluating potential partners for your Collapsible Gift Boxes project, prioritize those with comprehensive certification portfolios including ISO9001-2015 Quality Management System certification, which verifies systematic quality control implementation throughout the production process. These structured approaches to quality ensure consistent output and minimize defects across large production runs. Additionally, manufacturers implementing G7 Color Management certification demonstrate their capability to maintain precise color accuracy—a critical factor when your collapsible gift boxes must perfectly match your brand colors. Quality control processes should include multiple inspection points throughout the production workflow, from raw material testing to final product evaluation. Premium manufacturers utilize both automated inspection systems and trained quality control personnel to detect and address potential issues before products leave the facility. This comprehensive approach to quality assurance significantly reduces the risk of receiving substandard collapsible gift boxes that could damage your brand reputation or disrupt your product launch timelines.

Environmental Certifications and Sustainable Practices

In today's eco-conscious marketplace, packaging sustainability has evolved from a nice-to-have feature to a business imperative. When selecting a Collapsible Gift Boxes manufacturer, evaluate their environmental commitments through certifications such as ISO14001-2015 Environmental Management System and FSC certification. These credentials verify that your packaging partner maintains environmentally responsible practices throughout their operations and sources materials from responsibly managed forests. Beyond certifications, investigate how the manufacturer incorporates sustainability into their products and processes. For example, standard collapsible rigid-boxes can save more than 60% of shipping and storage costs compared to traditional gift boxes, significantly reducing the carbon footprint of transportation. Additionally, manufacturers committed to environmental stewardship typically offer recyclable and biodegradable material options for collapsible gift boxes without compromising on aesthetics or structural integrity. They may also implement energy-efficient production technologies, waste reduction programs, and closed-loop recycling systems within their facilities, further minimizing the environmental impact of your packaging production.

Social Responsibility and Ethical Manufacturing

The ethical dimensions of manufacturing operations increasingly influence consumer perceptions and brand reputation. When choosing a Collapsible Gift Boxes supplier, investigate their approach to social responsibility and ethical manufacturing practices. Certifications like Smeta (Sedex Members Ethical Trade Audit) indicate that a manufacturer adheres to recognized ethical standards regarding labor practices, health and safety, environmental impact, and business ethics. These credentials provide assurance that your collapsible gift boxes are produced under fair and humane working conditions. Additionally, evaluate the manufacturer's workplace policies, employee development programs, and community engagement initiatives. Reputable manufacturers typically maintain transparent relationships with their workforce, investing in proper training, fair compensation, and appropriate safety protocols. For instance, manufacturers with 300+ employees who invest in staff development—ensuring packaging specialists have at least three years of industry experience—demonstrate commitment to workforce quality and stability. This ethical approach to manufacturing not only aligns with corporate social responsibility objectives but also typically results in higher-quality collapsible gift boxes due to greater workforce engagement and reduced turnover of skilled personnel.

Customization Options and Service Quality

The flexibility to tailor packaging solutions to your specific needs and the quality of service provided throughout the process are critical factors that distinguish exceptional collapsible gift box manufacturers from merely adequate ones.

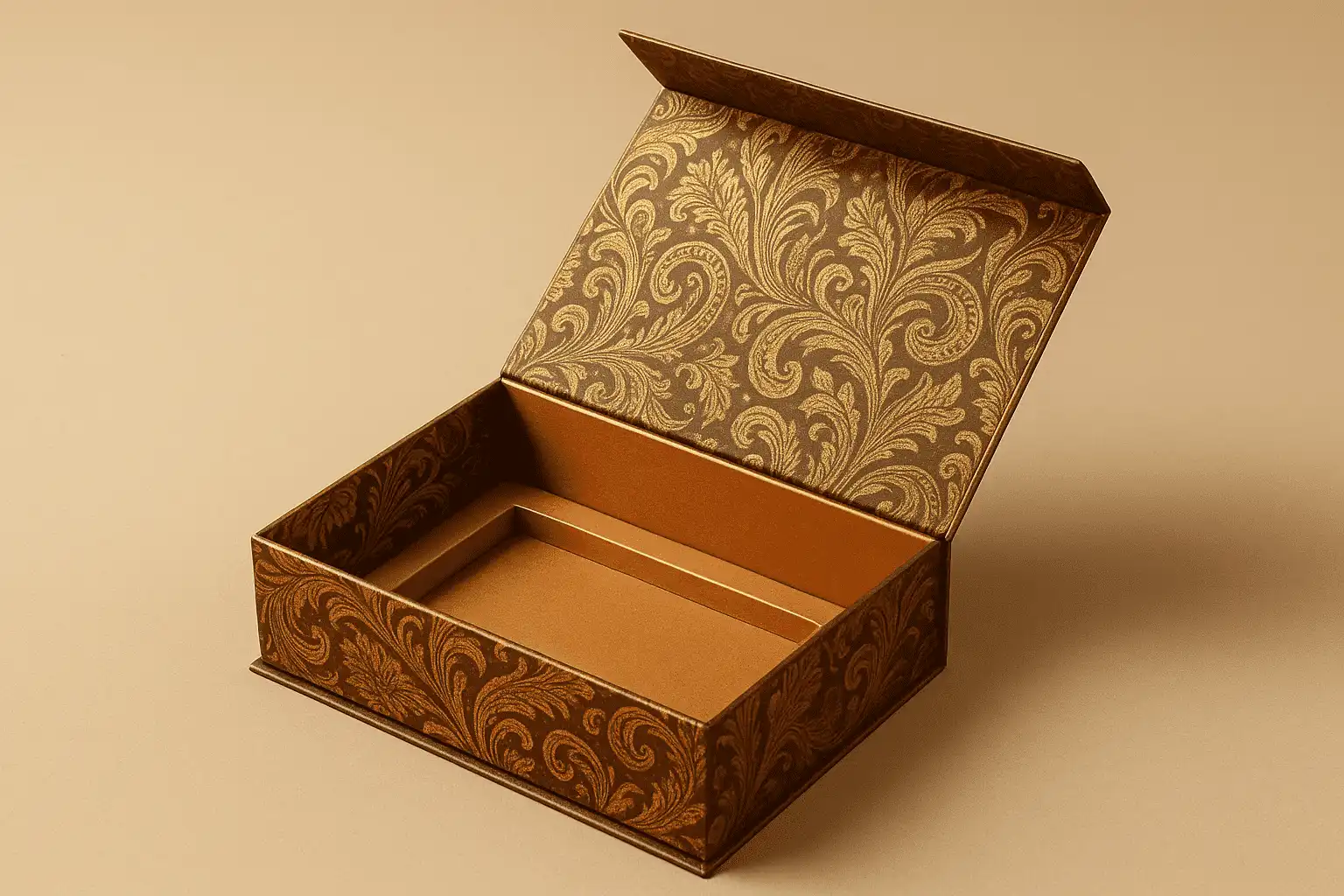

Design Flexibility and Finishing Options

The visual appeal and tactile experience of packaging significantly influence consumer perceptions of your product's value. Superior Collapsible Gift Boxes manufacturers offer extensive customization capabilities that allow your packaging to become a powerful brand communication tool. When evaluating potential partners, assess their range of finishing options—including cold or hot foil stamping, UV coating, frosted touch effects, and embossing techniques—that can dramatically enhance the visual impact of your collapsible gift boxes. These premium finishing techniques transform standard packaging into luxurious presentation pieces that elevate the unboxing experience. Additionally, examine the manufacturer's structural design capabilities. Innovative collapsible gift boxes with magnetic closures, ribbon pulls, or inserts can significantly enhance functionality while reinforcing brand identity. Expert manufacturers should also offer material variety, allowing you to select from different paperboard thicknesses, textures, and specialty papers to achieve your desired aesthetic and performance characteristics. Furthermore, leading manufacturers provide free 3D mock-up services and release monthly design inspirations, helping you visualize the final product before production and keeping your packaging concepts fresh and aligned with current market trends.

Communication Efficiency and Project Management

The quality of interaction between you and your Collapsible Gift Boxes manufacturer directly impacts project outcomes and customer satisfaction. Efficient communication channels and responsive project management systems ensure your packaging needs are correctly understood and implemented. When evaluating potential partners, prioritize manufacturers with experienced staff—ideally those with at least three years of specialized packaging knowledge—who can provide informed guidance throughout the production process. This expertise enables them to anticipate potential challenges and propose effective solutions before they become problems. Additionally, assess their communication protocols, including dedicated account management, regular project updates, and transparent timeline adherence. Responsive manufacturers typically acknowledge inquiries promptly and provide detailed answers to technical questions about collapsible gift boxes within 24 hours. Furthermore, effective project management systems include clearly defined milestones, structured approval processes, and dedicated quality control checkpoints. These systems ensure your collapsible gift boxes move efficiently through design, sampling, production, and delivery phases while maintaining quality standards. Manufacturers offering integrated project management platforms with real-time production tracking provide additional transparency and peace of mind throughout the manufacturing process.

Sampling Process and Customer Support

The pre-production sampling process reveals much about a manufacturer's attention to detail and commitment to customer satisfaction. When selecting a Collapsible Gift Boxes producer, evaluate their sampling policies and support services. Leading manufacturers offer both blank samples (typically free) and full CMYK printed samples (often subject to design requirements) to verify structural integrity, material quality, and print fidelity before full production. This sampling phase provides a critical opportunity to assess how your collapsible gift boxes will function and appear in real applications. Throughout the sampling process, responsive customer support demonstrates the manufacturer's client-centered approach. Technical specialists should be readily available to answer questions regarding material selection, structural stability, or printing specifications for your collapsible gift boxes. Additionally, evaluate the manufacturer's after-sales service policies, including strict compensation conditions that protect your interests if quality issues arise. Premium manufacturers typically maintain comprehensive quality records and offer clear resolution processes for addressing any defects or inconsistencies. Furthermore, value-added services such as packaging storage solutions, fulfillment assistance, or reordering systems indicate a manufacturer focused on building long-term relationships rather than simply completing transactions, ensuring ongoing support for your collapsible gift boxes needs as your business grows.

Conclusion

Selecting the right manufacturer for collapsible gift boxes requires careful evaluation of credentials, production capabilities, quality standards, and service quality. With 20 years of industry experience, 300+ skilled employees, and a 35,000m² manufacturing facility, Fetching Printing stands as an ideal partner for your premium packaging needs. Our patented designs save 20-30% in costs while enhancing visual appeal through advanced finishing techniques.

Are you ready to elevate your brand presentation with exceptional collapsible gift boxes? Join over 1,000 loyal customers who trust our comprehensive packaging solutions, backed by ISO certifications and sustainable practices. Our team of five senior engineers with over 10 years of experience is ready to transform your packaging vision into reality. Contact us today at support@fetchingprinting.com to discuss your specific requirements and discover how our innovative packaging solutions can drive your brand success.

References

1. Johnson, M. (2023). "Innovation in Collapsible Packaging: Trends and Applications." Packaging Technology and Science, 36(4), 218-231.

2. Zhang, L., & Thompson, R. (2024). "Sustainable Practices in Premium Gift Box Manufacturing." Journal of Cleaner Production, 412, 137289.

3. Williams, D., & Chen, H. (2022). "Quality Assurance Systems in Packaging Production." International Journal of Quality & Reliability Management, 39(7), 1565-1582.

4. Harris, S. (2023). "The Impact of Packaging Design on Consumer Perception and Purchase Intent." Journal of Business Research, 156, 113356.

5. Liu, Y., & Martinez, C. (2024). "Advancements in Collapsible Rigid Box Technology." Packaging Science and Engineering, 29(2), 89-103.

6. Anderson, P., & Kumar, V. (2023). "Evaluating Packaging Manufacturers: A Comprehensive Framework for Brand Owners." Journal of Supply Chain Management, 59(3), 57-78.

Based on your location and order quantity, you will have the opportunity to receive a limited time free shipping promotion!

Corporate Purpose