How Collapsible Rigid Boxes Help Cut Packaging and Shipping Costs?

Picture this scenario: You're shipping luxury products nationwide, but traditional rigid boxes consume warehouse space and drive freight expenses through the roof. Meanwhile, competitors slash operational costs while maintaining premium presentation. The solution lies in innovative collapsible rigid box technology that transforms how businesses approach packaging economics. This comprehensive guide reveals how switching to collapsible packaging can reduce logistics expenses by over 60% while preserving the luxury unboxing experience your customers expect.

Understanding the Cost Structure of Traditional Rigid Packaging

Traditional rigid gift boxes present significant financial challenges for businesses operating in competitive markets. Unlike folding cartons that arrive flat, conventional rigid boxes ship pre-assembled, creating substantial volume during transportation. Each shipment requires multiple containers to accommodate the bulky packaging, directly multiplying freight charges and carbon footprint. Warehouse storage presents another overlooked expense, as pre-assembled boxes occupy valuable floor space that could house finished inventory. Businesses with limited storage capacity often face difficult decisions between maintaining adequate packaging supplies and maximizing product storage. Furthermore, the construction method of traditional rigid boxes involves wrapping paper over a permanent chipboard frame, making disassembly impossible. This structural limitation means companies must accept inflated shipping volumes as an unavoidable cost of maintaining premium presentation standards for their products.

The manufacturing complexity of traditional rigid boxes also contributes to extended production timelines and increased labor costs. Each box requires manual assembly, wrapping, and quality inspection before shipping to clients. These labor-intensive processes translate directly into higher per-unit costs that squeeze profit margins, especially for small to medium-sized businesses. When businesses calculate total cost of ownership, including production, storage, and transportation, traditional rigid packaging often represents a significant portion of operational expenses that directly impact competitiveness in price-sensitive markets.

How Collapsible Rigid Box Design Reduces Shipping Expenses?

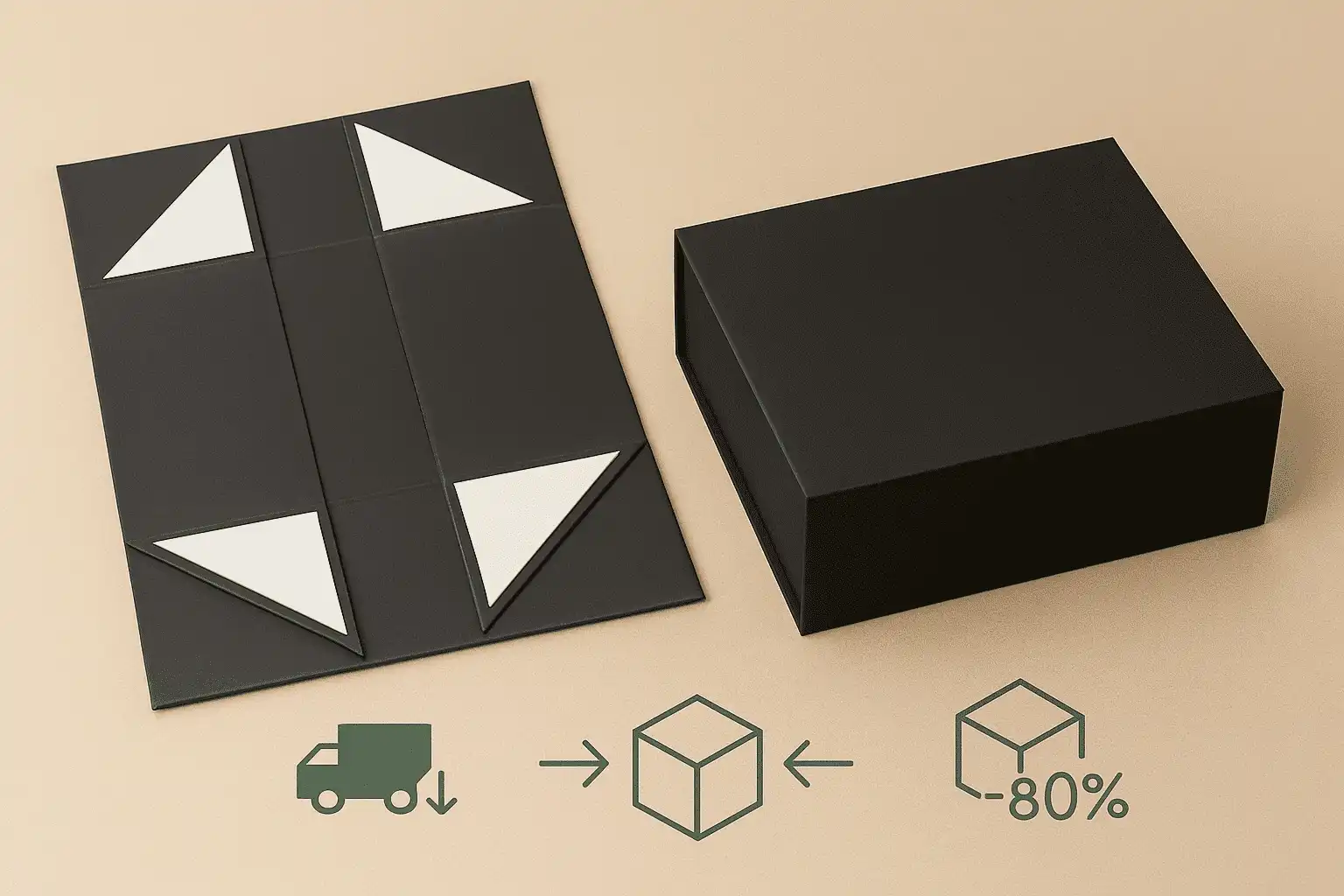

The innovative engineering behind collapsible rigid box structures delivers transformative cost savings through intelligent design principles. These boxes ship completely flat, reducing dimensional weight calculations that freight carriers use to determine shipping charges. A single pallet of flat collapsible rigid boxes can accommodate the equivalent of five to six pallets of traditional pre-assembled boxes, immediately multiplying shipping efficiency. This volume reduction translates directly to fewer shipment runs, reduced fuel consumption, and substantially lower transportation costs. Advanced collapsible rigid box designs incorporate proprietary folding mechanisms protected by patents, ensuring boxes maintain structural integrity while collapsing to minimal thickness during transport and storage.

When businesses implement collapsible rigid box solutions, they typically observe shipping cost reductions exceeding 60% compared to traditional rigid gift boxes. Even when compared against standard collapsible designs, proprietary structures can deliver additional savings of 20% to 30% through optimized engineering and material efficiency. The folding mechanism utilizes strategic scoring and magnetic closure systems that allow the box to self-assemble quickly without sacrificing the premium feel customers associate with rigid packaging. Grey chipboard or duplex chipboard construction provides the necessary rigidity and strength, while integrated hinges and closure points ensure boxes arrive flat but assemble into perfectly square, structurally sound containers within seconds.

Material Efficiency and Environmental Impact

Beyond immediate shipping savings, collapsible rigid box technology optimizes material usage throughout the supply chain. Traditional rigid boxes require extensive wrapping paper to cover all exterior surfaces of pre-assembled structures, often resulting in material waste during production. Collapsible designs minimize material requirements by utilizing single-sheet construction methods where printed paper bonds directly to chipboard substrates. This approach reduces raw material consumption while maintaining the premium aesthetic essential for luxury product packaging. Substrate options like SBS C1S or SBS C2S provide brilliant white printing surfaces ideal for vibrant color reproduction and specialty finishes, while the coated surfaces accept hot foil stamping, embossing, UV coating, and other premium decorative processes seamlessly.

Environmental considerations increasingly influence purchasing decisions across consumer segments, making sustainable packaging a competitive advantage rather than optional consideration. Collapsible rigid boxes manufactured from recycled grey chipboard or CCNB reduce environmental footprint without compromising structural performance. These materials maintain excellent rigidity and durability while supporting corporate sustainability initiatives. FSC certification options ensure responsible forestry practices, while the recyclable nature of paperboard substrates allows end users to dispose of packaging responsibly. Reduced shipping volume also decreases carbon emissions associated with transportation, creating measurable environmental benefits that resonate with eco-conscious consumers and corporate buyers committed to reducing supply chain environmental impact.

Warehouse Storage Optimization with Flat-Pack Packaging

Warehouse space represents one of the most expensive operational costs for businesses managing physical inventory and packaging supplies. Traditional rigid boxes demand disproportionate storage volume relative to their utility, as pre-assembled structures cannot nest or stack efficiently. A thousand traditional rigid gift boxes might require an entire pallet or multiple storage areas, consuming valuable warehouse real estate that could house revenue-generating inventory. This space inefficiency forces businesses to make difficult tradeoffs between maintaining adequate packaging reserves and maximizing product storage capacity. During peak seasons, insufficient storage space can create bottlenecks that delay order fulfillment and frustrate customers expecting rapid delivery.

Collapsible rigid box solutions fundamentally transform warehouse economics by shipping and storing completely flat until assembly becomes necessary. When flattened, these boxes occupy mere fractions of the space required by traditional rigid packaging, allowing businesses to maintain larger packaging inventories within existing storage footprints. A single pallet of flat collapsible boxes can replace five or six pallets of traditional rigid boxes, immediately freeing warehouse space for additional products or reducing overall facility costs. This storage efficiency proves especially valuable for businesses operating multiple facilities or those constrained by expensive urban warehouse locations where square footage directly impacts profitability. The space savings extend beyond primary warehousing to retail locations, fulfillment centers, and production facilities where packaging supplies must be readily accessible.

Production Flexibility and Just-in-Time Inventory Management

The compact storage profile of collapsible rigid boxes enables sophisticated inventory management strategies previously impractical with bulky traditional packaging. Businesses can maintain diverse packaging options without overwhelming storage capacity, offering customers multiple box sizes and styles for different product lines or seasonal promotions. This flexibility supports just-in-time inventory practices that minimize carrying costs while ensuring packaging availability matches demand fluctuations. Advanced collapsible rigid box production utilizes automated visual positioning systems that ensure consistent quality and rapid production cycles. Short production timelines and stable quality metrics allow businesses to order packaging supplies strategically, reducing inventory holding costs while maintaining fulfillment capabilities.

The assembly process itself represents another operational advantage, as collapsible rigid boxes require minimal training and workspace for preparation. Fulfillment staff can quickly assemble boxes as needed, eliminating the space requirements for pre-assembled packaging storage near packing stations. This operational flexibility supports lean manufacturing principles and reduces non-value-added handling throughout the fulfillment process. The magnetic closure systems and integrated folding mechanisms ensure boxes assemble consistently without specialized tools or extensive training, maintaining productivity even during seasonal hiring periods when temporary workers support operations.

Premium Presentation Without Premium Costs

One persistent misconception suggests cost-effective packaging necessarily compromises presentation quality or brand perception. Collapsible rigid box technology decisively refutes this assumption by delivering authentic luxury packaging experiences at significantly reduced total costs. When properly assembled, these boxes provide identical structural rigidity, premium tactile experience, and sophisticated appearance as traditional rigid gift boxes. The magnetic closure mechanisms create satisfying snap closures that signal quality and attention to detail. High-quality printing on SBS C2S substrates delivers exceptional color vibrancy and sharp detail reproduction that elevates brand presentation. Surface finishing options including spot UV coating, foil stamping in gold or silver, embossing and debossing, and soft-touch lamination ensure packaging communicates premium positioning effectively.

The versatility of collapsible rigid box customization allows brands to maintain distinctive visual identities while optimizing packaging economics. Metallic paper substrates create stunning reflective finishes perfect for luxury cosmetics or jewelry packaging. Brown kraft constructions deliver authentic, eco-conscious aesthetics that resonate with organic and handcrafted brand positions. CCNB substrates provide economical solutions for brands requiring quality printing at competitive price points without sacrificing visual impact. Each material option accepts diverse printing technologies and finishing processes, ensuring packaging aligns perfectly with brand guidelines while delivering measurable cost savings. The availability of three standardized sizes—Large for products 100-150mm height, Medium for 50-100mm products, and Tiny for 20-50mm items—ensures optimal fit across diverse product categories.

Applications Across Industries and Product Categories

Collapsible rigid box solutions serve diverse industries where premium presentation intersects with economic pressures. Cosmetics brands utilize these boxes for skincare sets, makeup collections, and fragrance presentations, where luxury packaging drives perceived value and gift-giving appeal. Fashion and apparel companies package accessories, small leather goods, and premium garments in collapsible rigid boxes that protect products during shipping while creating memorable unboxing experiences. Electronics manufacturers package headphones, smartwatches, and mobile accessories in sturdy collapsible boxes that convey technological sophistication and quality assurance. The food and beverage sector employs these boxes for gourmet chocolates, specialty teas, and premium gift sets where packaging directly influences purchase decisions and gift presentation.

Subscription box services particularly benefit from collapsible rigid box economics, as these businesses ship thousands of units monthly where per-box cost savings multiply dramatically across order volumes. The ability to customize printing and finishing allows subscription services to refresh packaging designs seasonally while maintaining cost efficiency. E-commerce businesses shipping direct to consumers appreciate the shipping volume reduction that lowers dimensional weight charges while the premium packaging enhances brand perception and reduces return rates. Corporate gift programs utilize collapsible rigid boxes for employee recognition, client appreciation, and promotional campaigns where impressive presentation must balance against budget constraints.

Ordering and Production Process Excellence

Implementing collapsible rigid box solutions begins with comprehensive demand consultation where packaging engineers assess specific product requirements, dimensional specifications, and performance expectations. This consultative approach ensures optimal box selection from available sizes or identifies opportunities for custom structure development. Solution design follows initial consultation, where business managers collaborate with clients to finalize material selections, printing specifications, and finishing processes. Professional designers create detailed mockups incorporating brand colors, logos, and desired aesthetic elements. The proprietary folding mechanisms protected by patents ensure structural performance meets demanding application requirements while maintaining the cost advantages that justify adoption.

Professional implementation transforms approved designs into physical samples that validate all specifications before full production authorization. This sampling phase confirms material performance, printing quality, and assembly functionality while providing opportunities for final adjustments ensuring complete satisfaction. Upon customer confirmation and deposit payment, production proceeds using advanced manufacturing technology including automated visual positioning systems that ensure dimensional accuracy and consistent quality across production runs. The printing process employs offset, digital, or flexographic methods depending on order volume and complexity. Surface finishing applies protective and decorative treatments including UV coatings, lamination, and specialty finishes. Die-cutting creates precise folding lines and shapes, while gluing and assembly prepare boxes for flat-pack shipping. Final packing ensures products arrive pristine and ready for immediate deployment.

Material Selection for Optimal Performance

Substrate selection critically influences both performance characteristics and cost structures for collapsible rigid box applications. SBS C1S paperboard manufactured from virgin bleached wood pulp provides exceptionally smooth printing surfaces on coated sides while maintaining strong adhesion properties on uncoated reverse surfaces. This substrate excels in applications requiring vibrant color reproduction and specialty finishing while offering recyclability and FSC certification options. SBS C2S delivers premium appearance with coating on both surfaces, enabling sophisticated interior printing for products where interior presentation contributes to unboxing experience. The clean, hygienic properties make SBS C2S ideal for food-contact applications and pharmaceutical packaging where purity standards mandate virgin fiber substrates.

CCNB represents economical alternatives combining clay-coated white printing surfaces with grey recycled backs, delivering reliable print performance at competitive costs. The high recycled content supports sustainability initiatives while maintaining adequate rigidity for most applications. Brown kraft substrates embrace natural, unbleached aesthetics that communicate environmental consciousness and artisanal authenticity. The inherent strength and tear resistance of kraft paper provide excellent durability for shipping and handling. Grey chipboard manufactured from compressed recycled pulp offers exceptional strength-to-cost ratios, making it ideal for internal structures requiring maximum rigidity. Duplex chipboard combines bright white coated printing surfaces with economical recycled grey cores, balancing visual appeal with cost efficiency across diverse applications.

Conclusion

Collapsible rigid box technology revolutionizes packaging economics by eliminating the artificial tradeoff between premium presentation and operational efficiency, delivering genuine cost savings exceeding 60% while maintaining luxury positioning.

Cooperate with GUANGZHOU FETCHING COLOR PRINTING & PACKAGING LTD.

As a trusted China collapsible rigid box manufacturer, China collapsible rigid box supplier, and China collapsible rigid box factory with over 25 years of experience since our 1999 founding, GUANGZHOU FETCHING COLOR PRINTING & PACKAGING LTD. offers High Quality collapsible rigid box solutions available for China collapsible rigid box wholesale. Our 50,000㎡ manufacturing facility equipped with KBA106 UV printing machines and Heidelberg XL162 presses serves over 1,000 loyal customers across food, cosmetics, personal care, and electronics industries. We maintain ISO14001, ISO9001, Smeta, G7, FSC, and Disney certifications while our R&D team of experienced packaging engineers develops innovative solutions in material applications, structure development, and process technology. Contact our team today for competitive collapsible rigid box price quotes and discover how our expertise transforms packaging challenges into competitive advantages. Reach us at public@fetchingprinting.com.

References

1. Smith, J. & Anderson, K. (2023). "Sustainable Packaging Solutions: Economic and Environmental Benefits of Collapsible Rigid Box Technology." Journal of Packaging Science and Technology, Vol. 45, No. 3.

2. Chen, L. (2024). "Cost Optimization in Luxury Packaging: A Comparative Analysis of Traditional and Collapsible Rigid Box Systems." International Journal of Supply Chain Management, Vol. 18, No. 2.

3. Thompson, R., Martinez, E. & Williams, D. (2023). "Space Efficiency and Transportation Cost Reduction Through Innovative Packaging Design." Logistics and Distribution Review, Vol. 32, No. 4.

4. Roberts, M. (2024). "Material Science Advances in Premium Collapsible Packaging: Balancing Aesthetics with Functionality." Packaging Technology Quarterly, Vol. 29, No. 1.

Based on your location and order quantity, you will have the opportunity to receive a limited time free shipping promotion!

Corporate Purpose