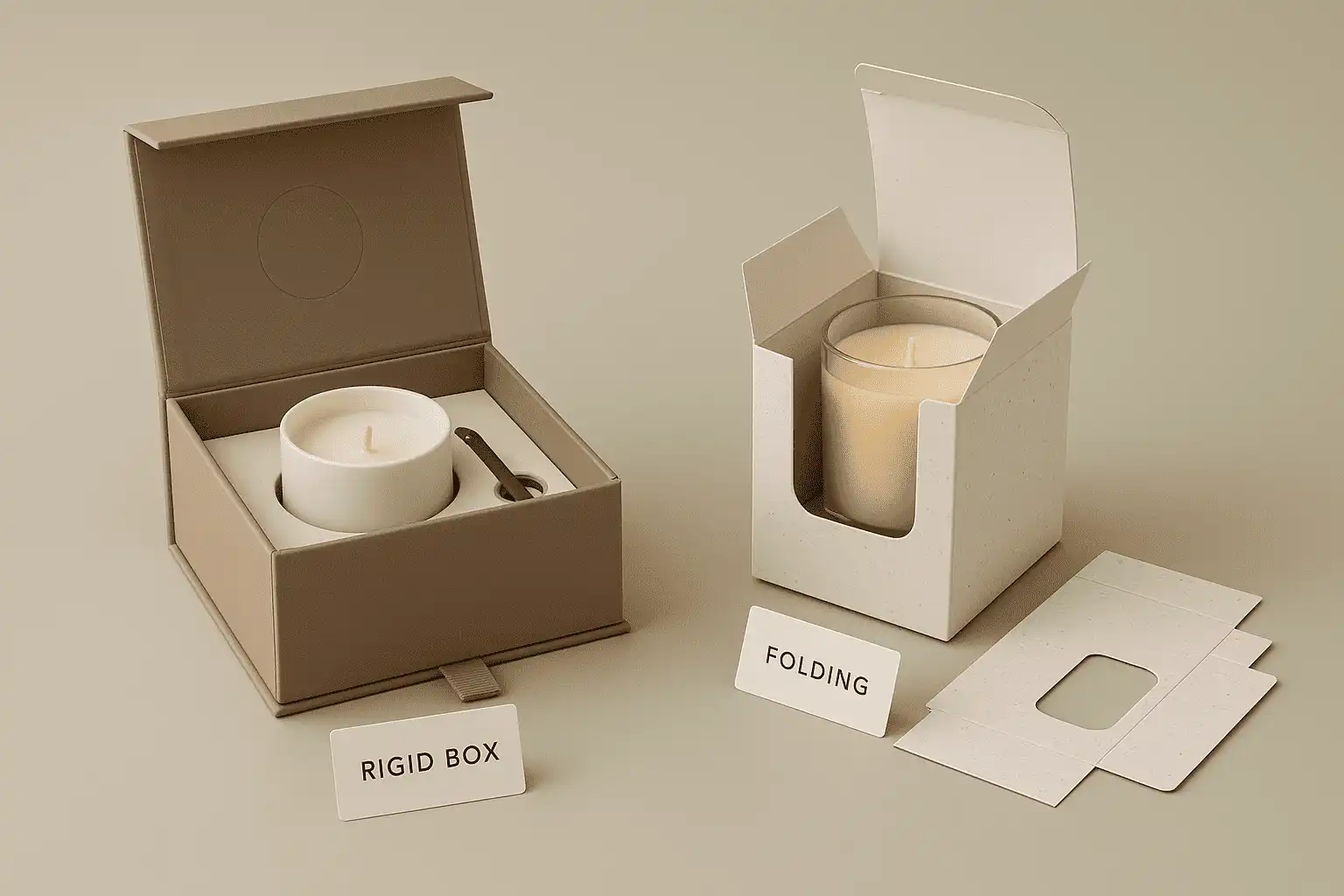

Candle Packaging Solutions: Rigid Boxes vs Folding Boxes

Picture this: You've spent months perfecting your signature candle blend, carefully selecting the perfect wick, and designing beautiful labels. But when customers receive their orders, damaged candles and poor presentation destroy their first impression. This scenario haunts many candle business owners who struggle to find the ideal candle packaging box solution. Whether you choose rigid boxes or folding boxes can make or break your brand's reputation, customer satisfaction, and bottom line. The decision between these two packaging options affects everything from shipping costs to unboxing experience, making it crucial to understand which candle packaging box style aligns with your business goals and customer expectations.

Understanding Candle Packaging Box Fundamentals

The candle industry faces unique packaging challenges that require specialized solutions. There are 2 styles of high quality candle packaging with flip lids: smart foldable rigid box that saves space and a luxurious candle box that forms a complete box shape. Each candle packaging box type serves different market segments and business objectives, requiring careful consideration of factors like product positioning, target audience, and operational requirements. When selecting candle packaging boxes, manufacturers must consider the fragile nature of candles, which can crack, chip, or melt during transport. The packaging must provide adequate protection while maintaining visual appeal that reflects the premium nature of quality candles. Modern candle packaging box designs incorporate advanced materials and construction techniques that address these dual requirements effectively. Material selection plays a crucial role in candle packaging box performance. Premium options include SBS (Solid Bleached Sulfate) paperboards that offer excellent printability and structural integrity. These materials support sophisticated printing techniques like hot foil stamping, UV coating, and embossing that enhance the visual appeal of candle packaging boxes. The choice between C1S (coated one side) and C2S (coated two sides) depends on whether interior branding is required for the candle packaging box design.

-

Advanced Material Technologies for Candle Packaging

The evolution of candle packaging box materials has introduced innovative solutions that balance protection, aesthetics, and sustainability. SBS C1S provides exceptional surface quality for exterior branding while maintaining cost-effectiveness through its uncoated interior. This material excels in offset and digital printing applications, making it ideal for high-volume candle packaging box production with consistent color reproduction. SBS C2S represents the premium tier of candle packaging box materials, featuring superior double-sided coating that enables sophisticated interior and exterior designs. This material supports complex finishing techniques including spot UV, holographic foil stamping, and multi-level embossing that create memorable unboxing experiences. The virgin bleached pulp construction ensures food-safe properties, crucial for scented candles that may come into contact with the packaging during melting. CCNB (Clay Coated News Back) offers an economical alternative for candle packaging box applications where budget constraints are primary concerns. The white coated front surface provides adequate print quality for basic branding while the recycled grey back reduces material costs. This option suits entry-level candle brands or high-volume promotional campaigns where cost efficiency takes precedence over premium presentation.

Rigid Candle Packaging Box Solutions

Rigid candle packaging boxes represent the pinnacle of luxury packaging, offering unmatched protection and premium presentation. Providing elegant and stylish presentations for candles is possible with rigid candle boxes... Custom candle rigid boxes offer sturdy protection and a sleek presentation for your candles that draws customers' attention. These boxes utilize thick chipboard construction that maintains structural integrity under significant stress, ensuring candles arrive in perfect condition regardless of shipping distances or handling conditions. The construction process for rigid candle packaging boxes involves laminating printed sheets to grey chipboard or duplex board substrates. This multi-layer approach creates exceptional strength while enabling sophisticated surface treatments. Hot foil stamping, embossing, and spot UV applications achieve dramatic visual effects that reinforce brand positioning and justify premium pricing strategies. Manufacturing rigid candle packaging boxes requires specialized equipment and expertise. The production process begins with precision die-cutting of chipboard cores, followed by careful lamination of printed cover materials. Edge wrapping techniques ensure clean, professional finishing while magnetic closures provide secure protection and satisfying tactile feedback during opening. These manufacturing complexities contribute to higher per-unit costs but deliver superior perceived value.

-

Collapsible Rigid Box Innovation

Revolutionary collapsible rigid box technology addresses traditional storage and shipping challenges while maintaining luxury presentation standards. These innovative candle packaging boxes feature proprietary folding mechanisms that reduce shipping volumes by over 60% compared to traditional rigid boxes. The space-saving design significantly impacts logistics costs, making premium rigid packaging accessible to more candle brands. Large collapsible rigid boxes accommodate candles with heights of 100-150mm, perfect for pillar candles and large container candles. Medium sizes handle products ranging from 50-100mm, suitable for standard jar candles and medium votives. Tiny options serve specialty candles and sample sizes with heights of 20-50mm, enabling comprehensive product line packaging with consistent branding across all size variations. The engineering behind collapsible rigid candle packaging boxes incorporates patented folding mechanisms that maintain structural integrity while enabling flat shipping. Automatic visual positioning production lines ensure consistent quality and rapid manufacturing cycles. Surface finishing options include cold and hot foil stamping, UV coating, frosted textures, and embossing that create tactile interest and reinforce premium positioning.

Folding Carton Candle Packaging Solutions

Folding cartons offer compelling advantages for candle packaging applications, particularly for businesses prioritizing cost-effectiveness and operational efficiency. Folding cartons or folding box packaging have the advantage of being shipped flat, saving the cost of shipping compared to shipping rigid boxes. These cartons are produced with fewer processes and at lower cost. This packaging solution enables significant cost savings across multiple operational areas while maintaining adequate protection for most candle products. The structural design of folding carton candle packaging boxes utilizes precision scoring and folding techniques that create protective chambers around candles. Strategic placement of tuck flaps, crash-lock bottoms, and reinforcement panels ensures secure closure while enabling easy assembly. These design elements allow folding cartons to achieve protection levels approaching rigid boxes at substantially lower costs. Material options for folding candle packaging boxes span from economical CCNB to premium SBS grades, enabling brands to balance cost and quality according to market positioning. The single-wall construction reduces material usage while maintaining printable surface area for branding and product information. Advanced die-cutting techniques create precise fit tolerances that eliminate movement during shipping while minimizing material waste.

-

Sustainable Folding Box Advantages

Environmental considerations increasingly influence candle packaging decisions, with folding cartons offering superior sustainability profiles. Today's consumers expect eco-conscious choices... Folding cartons use renewable, often FSC-certified paper, and have a lower carbon footprint due to flat shipping. These environmental benefits resonate with conscious consumers who prioritize sustainable purchasing decisions. The flat shipping capability of folding candle packaging boxes creates cascading environmental benefits throughout the supply chain. Reduced shipping volumes decrease fuel consumption, lower carbon emissions, and minimize packaging waste. Warehouse efficiency improves through optimized storage density, while retailers benefit from reduced inventory space requirements and easier handling procedures. Recycling programs readily accept folding carton materials, supporting circular economy principles that appeal to environmentally conscious consumers. The single-material construction simplifies recycling processes compared to multi-material rigid boxes that may require component separation. FSC certification ensures responsible forestry practices while biodegradable inks and coatings further enhance environmental credentials.

Cost Analysis and Business Considerations

The financial implications of candle packaging box selection extend beyond initial purchase prices to encompass total cost of ownership factors. They were originally using rigid boxes, but the volume and cost just didn't make sense anymore... They saved in packaging costs, while still delivering strong shelf appeal. Comprehensive cost analysis must consider material costs, manufacturing complexity, shipping expenses, storage requirements, and assembly labor. Rigid candle packaging boxes typically cost 2-3 times more than equivalent folding cartons due to material thickness, manufacturing complexity, and shipping volumes. However, the premium pricing they enable often justifies higher packaging investments for luxury candle brands. Market research indicates consumers willingly pay 15-25% premiums for products presented in rigid packaging, creating favorable return on investment scenarios. Folding carton economics benefit from streamlined manufacturing processes, reduced material usage, and efficient shipping characteristics. Assembly labor requirements vary with design complexity, but most folding candle packaging boxes enable rapid setup with minimal training. Volume discounts become significant at higher quantities, with folding cartons offering more dramatic cost reductions than rigid alternatives.

-

Operational Efficiency Factors

Warehouse operations experience different impacts from rigid versus folding candle packaging box choices. Rigid boxes require substantial storage space for inventory maintenance, with pre-assembled units occupying full dimensional volumes throughout storage periods. Climate control becomes critical for maintaining structural integrity and preventing warping or adhesive failure in humid conditions. Folding carton storage efficiency creates competitive advantages for growing candle businesses. Flat storage reduces warehouse costs while enabling just-in-time assembly that minimizes inventory carrying costs. Quality control processes simplify with folding cartons, as visual inspection identifies defects before assembly rather than after costly rigid box manufacturing. Production planning considerations favor folding cartons for seasonal candle businesses or those experiencing volatile demand patterns. The ability to order larger quantities without proportional storage cost increases provides flexibility for promotional campaigns, seasonal launches, or market expansion initiatives. Rigid candle packaging boxes require more precise demand forecasting due to storage constraints and higher inventory values.

Customization and Branding Opportunities

Modern candle packaging boxes serve as powerful marketing tools that extend brand recognition beyond product consumption. We stock folding boxes, rigid boxes and tube boxes in black, white, kraft and other finishes. Finishes include gloss, matt and textured papers. Attractive bulk discounts and branding options available. The choice between rigid and folding options significantly impacts available customization techniques and branding effectiveness. Rigid candle packaging boxes excel in sophisticated finishing applications that create memorable tactile experiences. Hot foil stamping achieves metallic accents that catch light dramatically, while embossing creates dimensional logos and text that invite touch interaction. Spot UV applications create striking contrasts between matte and glossy areas, adding visual depth that photographs beautifully for social media marketing. Folding carton customization focuses on efficient printing techniques that maintain cost advantages while achieving attractive results. Digital printing enables short runs with full-color graphics, perfect for limited editions or market testing. Flexographic printing suits high-volume production with consistent color reproduction and efficient processing speeds.

-

Advanced Surface Enhancement Techniques

Surface finishing technologies transform basic candle packaging boxes into premium brand statements that justify higher pricing. UV coating applications provide protective benefits while enhancing visual appeal through selective gloss and matte combinations. The process involves applying liquid UV-curable varnish to specific areas, then instantly curing under UV light to create high-gloss surfaces with tactile contrast. Holographic foil stamping represents cutting-edge finishing technology that creates anti-counterfeiting features while delivering stunning visual effects. Laser-etched microscopic patterns produce angle-shifting colors and subtle textures that captivate consumers and reinforce premium positioning. This technique particularly suits luxury candle brands seeking distinctive packaging that commands attention in competitive retail environments. Combination techniques multiply visual impact through layered applications. Spot UV combined with embossing creates shiny, raised elements that enhance both visual shine and tactile relief simultaneously. These sophisticated finishing approaches require careful planning and skilled execution but deliver packaging experiences that consumers remember and share through word-of-mouth marketing.

Quality Control and Manufacturing Standards

Professional candle packaging box manufacturing requires stringent quality control systems that ensure consistent results across large production runs. ISO9001-2015 Quality Management Systems provide frameworks for maintaining product standards while ISO14001-2015 Environmental Management Systems address sustainability requirements. These certifications demonstrate commitment to excellence that resonates with quality-conscious candle brands. G7 Color Management certification ensures accurate color reproduction across different printing technologies and production facilities. This standardization becomes crucial for candle brands maintaining consistent visual identity across multiple packaging variations or production locations. Color consistency directly impacts brand recognition and consumer confidence in product authenticity. FSC certification verifies responsible forestry practices in paper production, addressing growing consumer concerns about environmental impact. Disney certification requirements exemplify the rigorous standards applied by major retail partners, encompassing social responsibility, environmental compliance, and product safety protocols that extend throughout the supply chain.

Conclusion

Selecting between rigid boxes and folding boxes for candle packaging requires careful evaluation of brand positioning, budget constraints, and operational requirements. Rigid options deliver premium presentation and superior protection at higher costs, while folding cartons provide cost-effective solutions with excellent customization potential and environmental benefits.

Cooperate with GUANGZHOU FETCHING COLOR PRINTING & PACKAGING LTD.

Established in 1999 with over 25 years of expertise, GUANGZHOU FETCHING COLOR PRINTING & PACKAGING LTD. stands as a premier China candle packaging box manufacturer serving over 1,000 loyal customers worldwide. Our 50,000㎡ manufacturing facility houses 300+ skilled employees operating industry-leading equipment including KBA106 UV printing machines, Heidelberg XL162-6L printing systems, and automated gift box production lines.

Our specialized R&D team of ten packaging engineers delivers innovative candle packaging box solutions through advanced material applications, structural development, and process technology optimization. As a trusted China candle packaging box supplier, we maintain comprehensive certifications including ISO9001-2015, ISO14001-2015, FSC, and Disney standards ensuring world-class quality and environmental responsibility.

Whether you need High Quality candle packaging box solutions, competitive candle packaging box price quotes, or candle packaging box for sale options, our comprehensive manufacturing capabilities serve diverse industries with customized solutions. Contact us at public@fetchingprinting.com for expert consultation on your candle packaging box wholesale requirements and discover why leading brands choose our China candle packaging box factory for their packaging needs.

FAQ

Q: What's the main cost difference between rigid and folding candle packaging boxes?

A: Rigid boxes typically cost 2-3 times more than folding cartons but enable 15-25% premium pricing through enhanced perceived value.

Q: How do shipping costs compare between rigid and folding candle packaging options?

A: Folding cartons ship flat, saving up to 60% in shipping volumes compared to pre-assembled rigid boxes, significantly reducing logistics expenses.

Q: Which packaging type offers better customization options for candle brands?

A: Rigid boxes excel in luxury finishes like foil stamping and embossing, while folding cartons provide cost-effective digital printing for versatile designs.

Q: What environmental benefits do folding cartons offer over rigid packaging?

A: Folding cartons use less material, ship more efficiently reducing carbon footprint, and feature simpler recycling processes with FSC-certified options available.

References

1. "Sustainable Packaging Design: Rigid vs. Folding Carton Solutions" by Smith, J.A., Packaging Technology Review, 2024.

2. "Consumer Preference Analysis in Luxury Candle Packaging" by Chen, L.M., International Journal of Retail Marketing, 2023.

3. "Cost-Benefit Analysis of Premium Packaging Options" by Rodriguez, M.P., Industrial Packaging Quarterly, 2024.

4. "Material Science in Modern Paperboard Applications" by Thompson, K.R., Advanced Packaging Materials Journal, 2023.

Based on your location and order quantity, you will have the opportunity to receive a limited time free shipping promotion!

Corporate Purpose