Avoiding Common Mistakes When Using Rigid Collapsible Boxes

Picture this scenario: your premium product arrives at a customer's doorstep in a damaged, poorly assembled, or structurally compromised packaging. The excitement of unboxing transforms into disappointment, and your brand's reputation suffers. Many businesses struggle with Rigid Collapsible Boxes implementation, leading to costly errors, customer dissatisfaction, and wasted resources. Understanding and avoiding these common pitfalls is crucial for maintaining product integrity, reducing shipping costs, and delivering exceptional customer experiences. This comprehensive guide reveals the most frequent mistakes businesses make when utilizing Rigid Collapsible Boxes and provides actionable solutions to ensure optimal packaging performance across all applications.

Understanding Rigid Collapsible Box Fundamentals

The foundation of successful Rigid Collapsible Boxes implementation begins with understanding their unique construction and functionality. Unlike traditional rigid boxes that arrive pre-assembled, Rigid Collapsible Boxes feature an innovative folding mechanism that allows them to be shipped flat and assembled when needed. This design breakthrough offers significant cost savings in shipping and storage while maintaining the premium appearance and structural integrity that brands demand for luxury products. Many businesses fail to recognize that Rigid Collapsible Boxes require specific handling protocols during assembly and filling operations. The collapsible nature means that certain stress points need reinforcement, and the assembly sequence must follow precise steps to ensure optimal performance. Professional manufacturers develop proprietary folding mechanisms that balance ease of assembly with structural stability, creating boxes that can withstand the rigors of shipping while providing an exceptional unboxing experience.

-

Material Selection and Structural Integrity

The choice of substrate material significantly impacts the performance and durability of Rigid Collapsible Boxes. Premium options like SBS C1S and SBS C2S provide superior strength and printability, while economical choices like CCNB offer cost-effective solutions for specific applications. Each material type brings distinct characteristics that must align with your product requirements, shipping conditions, and brand positioning. Structural integrity depends on proper material thickness selection, appropriate adhesive application, and precise die-cutting tolerances. Many businesses underestimate the importance of working with manufacturers who understand these technical requirements and can recommend optimal material combinations based on specific use cases and performance expectations.

Critical Size and Dimension Planning Mistakes

One of the most costly mistakes businesses make involves inadequate size planning for their Rigid Collapsible Boxes. The collapsible design requires precise dimensional calculations that account for both the assembled state and the folding mechanism tolerances. Many companies fail to consider how the collapsible structure affects internal dimensions and product fit, leading to loose products that shift during shipping or tight fits that stress the box structure. Professional sizing involves understanding the relationship between external dimensions, internal capacity, and wall thickness variations that occur during the folding process. Large Rigid Collapsible Boxes suitable for products with heights of 100-150mm require different structural considerations than Medium boxes designed for 50-100mm products or Tiny boxes optimized for 20-50mm items. Each size category demands specific fold patterns, adhesive placement, and reinforcement strategies to ensure optimal performance.

-

Assembly Tolerance and Fit Considerations

The assembly process for Rigid Collapsible Boxes introduces variables that affect final dimensions and product fit. Temperature, humidity, and assembly force all influence how the box takes its final shape, and these factors must be considered during the design phase. Businesses often overlook these variables, resulting in boxes that perform inconsistently across different environmental conditions or assembly scenarios. Proper planning includes testing box assembly under various conditions and establishing clear assembly protocols that ensure consistent results. This includes training for assembly personnel, quality control checkpoints, and documentation of optimal assembly procedures that maintain both structural integrity and dimensional accuracy throughout the production process.

Material and Finishing Selection Errors

The sophisticated nature of Rigid Collapsible Boxes demands careful attention to material compatibility and finishing process integration. Many businesses make critical errors in combining materials and finishes that compromise the collapsible functionality or create weak points in the structure. For example, certain UV coating applications can affect fold flexibility, while inappropriate adhesive selection can lead to delamination during the folding process. Understanding how different finishing techniques interact with the collapsible mechanism is essential for successful implementation. Hot foil stamping, embossing, and specialty coatings must be strategically placed to avoid interference with fold lines and assembly points. The timing of finishing processes relative to die-cutting and folding preparation also affects final product quality and functionality.

-

Surface Treatment and Fold Line Compatibility

The integration of surface treatments with fold line requirements presents unique challenges in Rigid Collapsible Boxes production. Coating applications, lamination processes, and specialty finishes must be carefully planned to ensure they enhance rather than compromise the folding mechanism. Many businesses discover too late that their chosen finishing combinations create stress points or interfere with smooth assembly operations. Professional finishing strategies involve testing finish compatibility with fold requirements early in the development process. This includes evaluating how different coating thicknesses affect fold flexibility, how lamination adhesives interact with box adhesives, and how specialty finishes perform under the mechanical stress of repeated folding and assembly operations.

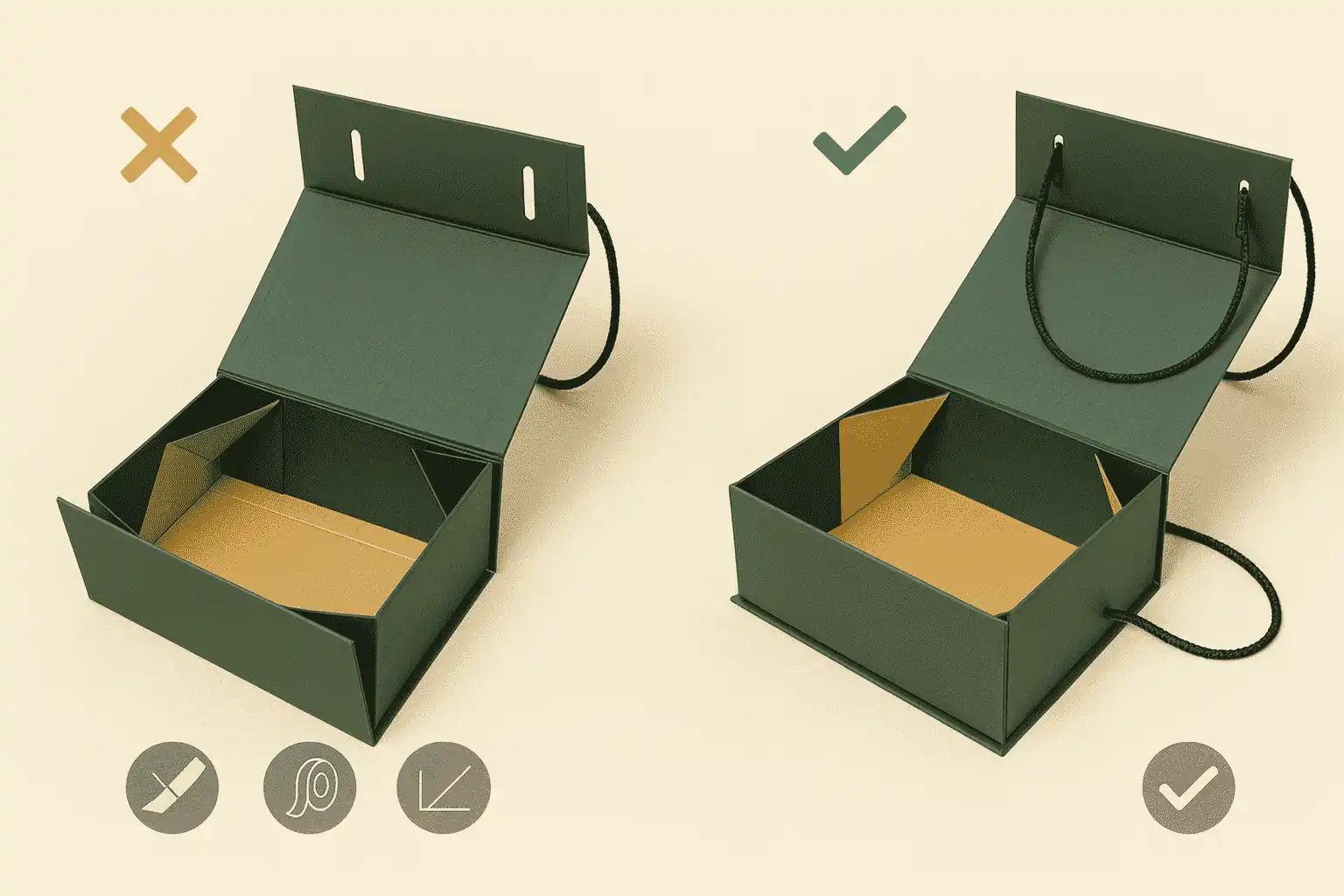

Assembly and Handling Protocol Failures

The unique assembly requirements of Rigid Collapsible Boxes demand specific protocols that many businesses fail to establish or properly implement. Unlike traditional packaging that arrives ready to use, these boxes require understanding of proper folding sequences, force application, and quality verification procedures. Improper assembly techniques can damage the structural integrity, affect appearance, or create safety hazards during handling. Successful implementation requires comprehensive training programs for all personnel who handle Rigid Collapsible Boxes during assembly, filling, or shipping operations. This includes understanding the mechanical properties of the folding mechanism, recognizing signs of assembly errors, and implementing corrective procedures that maintain consistent quality standards throughout the packaging process.

-

Quality Control and Inspection Procedures

Establishing robust quality control procedures specific to Rigid Collapsible Boxes is essential for maintaining consistent performance and avoiding costly errors. Many businesses apply standard rigid box inspection criteria without considering the unique aspects of collapsible construction, leading to oversight of critical issues that can compromise box performance during shipping or end-use. Effective quality control includes inspection of fold line integrity, assembly mechanism functionality, and structural stability under various stress conditions. This involves developing specific test procedures that evaluate box performance throughout its intended lifecycle, from assembly through shipping to end-user handling and disposal.

Storage and Shipping Optimization Oversights

The primary advantage of Rigid Collapsible Boxes lies in their ability to ship flat and assemble when needed, providing substantial cost savings in storage and transportation. However, many businesses fail to optimize their logistics operations to fully capitalize on these benefits. Improper storage conditions can affect the folding mechanism, while inadequate shipping protection can damage boxes before assembly. Maximizing the economic benefits requires understanding how environmental conditions affect stored boxes, implementing proper inventory rotation procedures, and establishing shipping protocols that protect the folding mechanism during transit. The space savings potential of over 60% compared to traditional rigid boxes can only be realized through proper logistics planning and execution.

-

Inventory Management and Environmental Control

The flat-pack nature of Rigid Collapsible Boxes requires modified inventory management approaches that account for their unique storage requirements. Humidity control becomes critical for maintaining fold line flexibility, while temperature variations can affect adhesive performance and dimensional stability. Many businesses overlook these environmental factors, leading to assembly difficulties or performance inconsistencies. Professional inventory management includes environmental monitoring, proper stacking procedures, and rotation protocols that ensure boxes maintain optimal condition throughout the storage period. This involves understanding how different materials respond to environmental variations and implementing control measures that preserve functionality until assembly and use.

Conclusion

Successfully implementing Rigid Collapsible Boxes requires attention to fundamental design principles, material selection, assembly protocols, and logistics optimization. By avoiding common mistakes in sizing, material compatibility, finishing integration, and handling procedures, businesses can fully realize the cost savings and performance benefits these innovative packaging solutions provide while maintaining the premium brand experience customers expect.

Cooperate with GUANGZHOU FETCHING COLOR PRINTING & PACKAGING LTD.

Established in 1999, GUANGZHOU FETCHING COLOR PRINTING & PACKAGING LTD. brings over 25 years of packaging expertise to help businesses avoid costly Rigid Collapsible Boxes mistakes. Our 50,000㎡ manufacturing facility houses industry-leading equipment including KBA106 UV printing machines, Heidelberg XL162-6L presses, and AI-powered gift box production lines operated by over 300 skilled professionals.

Our comprehensive R&D department, staffed by more than ten packaging engineers with extensive experience, specializes in developing innovative Rigid Collapsible Boxes solutions that eliminate common implementation errors. We offer three patented size configurations—Large (100-150mm), Medium (50-100mm), and Tiny (20-50mm)—each engineered to deliver optimal performance while providing over 60% cost savings compared to traditional rigid boxes.

With certifications including ISO14001-2015, ISO9001-2015, Smeta, G7 Color Management, FSC, and Disney approval, we ensure every Rigid Collapsible Boxes project meets the highest quality standards. Our automated visual positioning production lines deliver consistent results with shortened production times, while our comprehensive finishing capabilities including hot foil stamping, UV coating, and embossing create stunning visual effects without compromising structural integrity.

As a leading China Rigid Collapsible Boxes factory and China Rigid Collapsible Boxes supplier, we serve as your trusted China Rigid Collapsible Boxes manufacturer providing China Rigid Collapsible Boxes wholesale solutions. Discover our High Quality Rigid Collapsible Boxes for sale at competitive Rigid Collapsible Boxes price points. Contact us at public@fetchingprinting.com to discuss your specific requirements and avoid costly packaging mistakes. Your success is our success.

FAQ

Q: What are the most critical mistakes to avoid when assembling Rigid Collapsible Boxes?

A: The most critical mistakes include improper fold sequence, excessive force application, and neglecting to verify structural integrity after assembly. Always follow manufacturer guidelines and train personnel properly.

Q: How do environmental conditions affect Rigid Collapsible Boxes performance?

A: Temperature and humidity significantly impact fold line flexibility and adhesive performance. Maintain controlled storage conditions and allow boxes to acclimate before assembly to ensure optimal functionality.

Q: What material considerations are essential for Rigid Collapsible Boxes success?

A: Material selection must balance strength, flexibility, and finishing compatibility. Consider substrate thickness, coating interactions with fold lines, and adhesive compatibility to avoid structural failures.

Q: How can businesses optimize cost savings with Rigid Collapsible Boxes?

A: Maximize savings through proper logistics planning, inventory optimization, and assembly protocol implementation. Focus on storage efficiency, shipping volume reduction, and assembly time minimization for best results.

References

1. "Packaging Design and Manufacturing Guidelines for Collapsible Rigid Structures" - International Packaging Institute, Dr. Sarah Chen

2. "Material Science Applications in Premium Packaging Solutions" - Journal of Packaging Technology, Prof. Michael Roberts

3. "Quality Control Standards for Folding Box Manufacturing" - Packaging Industry Standards Board, Technical Committee

4. "Cost Optimization Strategies in Modern Packaging Operations" - Industrial Packaging Review, Manufacturing Research Group

Based on your location and order quantity, you will have the opportunity to receive a limited time free shipping promotion!

Corporate Purpose